The PAT-Core Concept

The PAT-Core: Enabling Battery Studies of Unmatched Quality

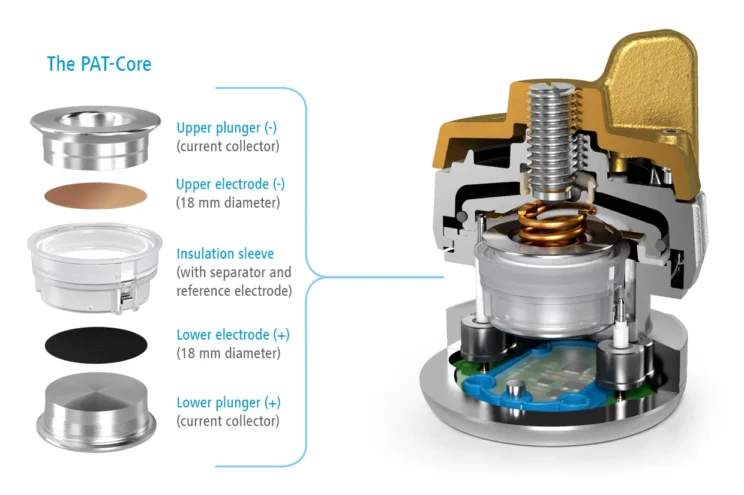

The PAT-Core is the world-wide patented*, essential part of the PAT-Cell. It holds the electrodes undergoing testing in place and allows for precise, concentric alignment of the cell stack. The well-defined geometry of the PAT-Core enables high-quality two- and three-electrode tests of Li-ion and other battery materials as well as supercapacitors. It is even suitable for special applications, such as printed electrodes.

The easy assembly of the PAT-Core minimizes the human factor in experiment preparation and even qualifies for robotic assembly.

The standard PAT-Core comprises three components. The first part is a highly customizable insulation sleeve with a built-in separator and ring-shaped reference electrode. Different reference materials, like sodium or magnesium, and various separator materials, such as glass fibre or microporous polyolefin, are available. The single-use concept reduces lab lead times and minimizes the risk of cross-contamination. The insulation sleeve is preassembled under a protective argon atmosphere at the EL-CELL factory to ensure consistent quality for reproducible battery tests. PEEK is available as an alternative material for the insulation sleeve, allowing us also to offer a reusable version for self-assembly.

The upper and lower plungers complete the PAT-Core and serve as current collectors. Battery researchers can choose from a broad range of different materials: battery-grade aluminum and copper, reusable stainless steel or precious metals, such as gold or platinum for special demands.

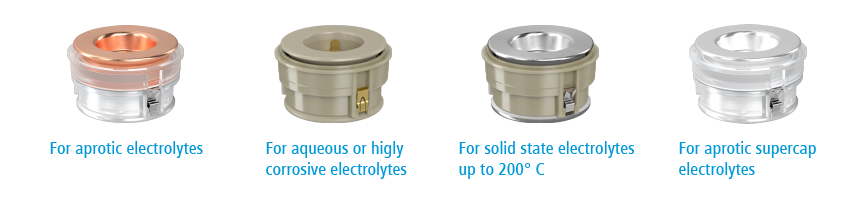

This way the PAT-Core is ready for both aprotic and aqueous electrolytes as well as special purposes such as high temperature environments.

*Patents: EP3108224, US10,408,781B2, ZL201480075905.3: REFERENCE ELECTRODE INSERT FOR AN ELECTROCHEMICAL TEST CELL – PAT-Core

The PAT-Core: A modular concept to fit almost all testing purposes

PAT-Core features

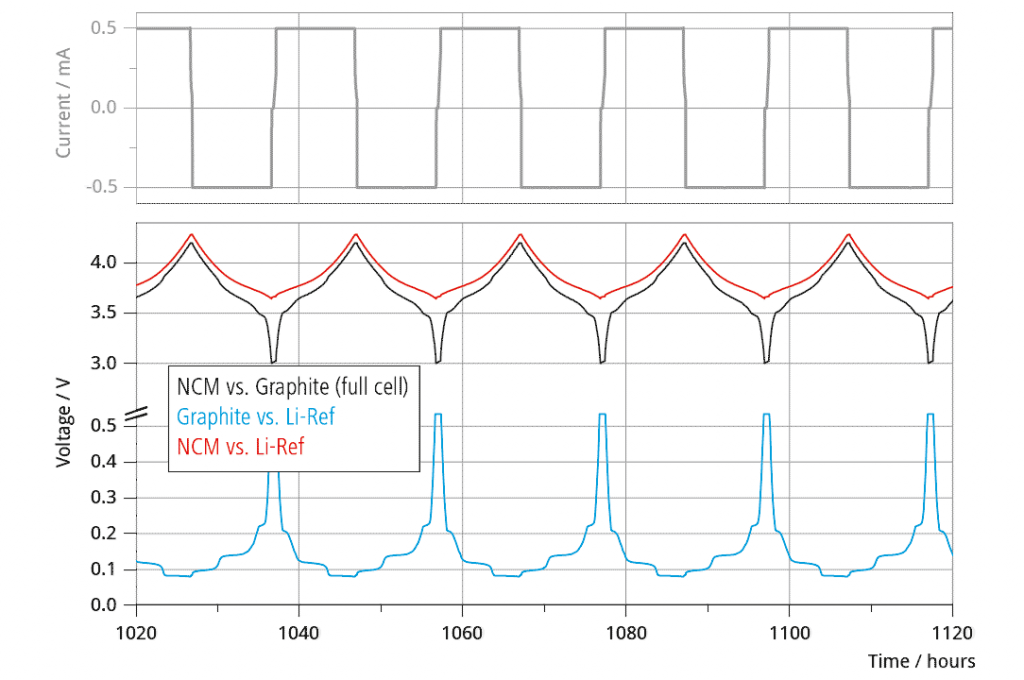

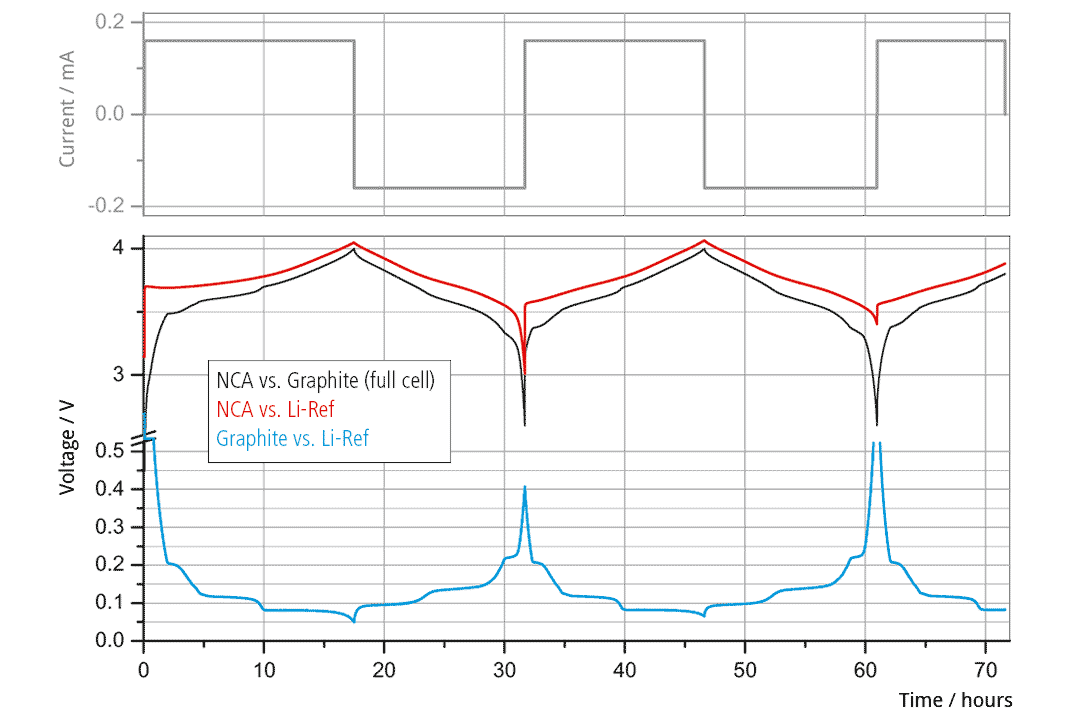

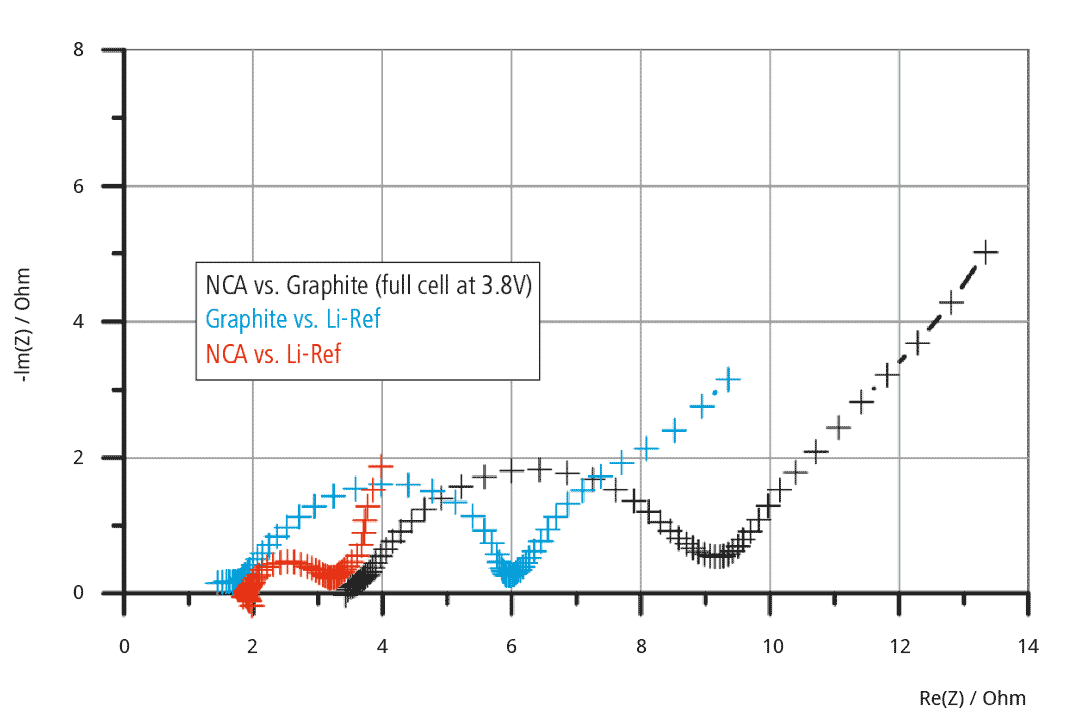

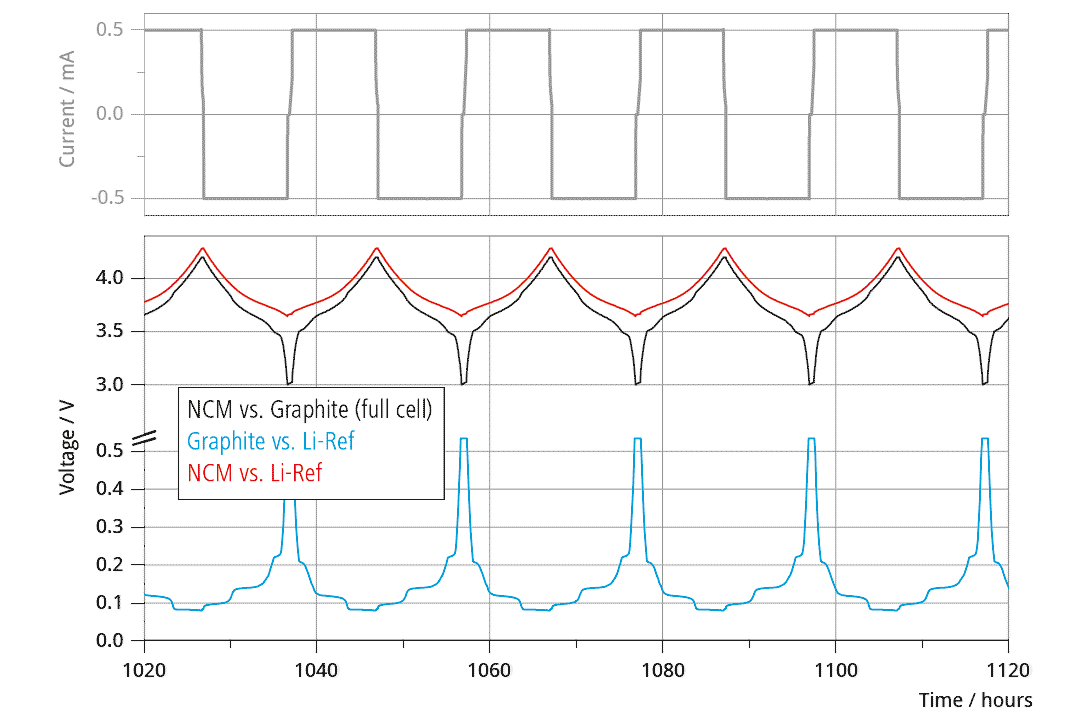

Long-term tests

The PAT-Core enables battery tests with a three-electrode setup and a duration of 1000 hours or more. This advantage is due to the new ring-shaped Li-reference electrode, which is far more time stable than point-type reference electrodes. The PAT-Core is, therefore, the perfect test system for aging studies.

Less cross contamination and corrosion

The single-use concept of the PAT series helps to reduce cross contamination between subsequent tests. Corrosion issues are also reduced. The PAT-Core consists of three single-use parts: insulation sleeve (PP), upper plunger (Cu as standard), and lower plunger (Al as standard).

All these parts are assembled, packed, and sealed under controlled atmosphere at the EL-CELL® factory. Moreover, single-use parts do not need to be cleaned and dried, which circumvents the risk of contamination with water and reduces the effort in the lab.

Please note that upper and lower plungers are also available as reusable versions in stainless steel.

Easy electrolyte filling

The PAT-Cell can be easily filled with electrolyte during the assembly procedure. The user needs only a micro-pipette to drip a defined amount of electrolyte onto the separator, which is factory preinstalled in the insulation sleeve of the PAT-Core.

The amount of electrolyte used is typically between 50 and 200μL, depending on the specific components used.

Tight test cells

The PAT-Cell is completely airtight and designed to operate outside of the glove box. This is ensured by special seals available in different materials like PE, PTFE or Al.

Furthermore, all PAT-Cell variants are helium leak tested at the EL-CELL factory to guarantee ultra-low leakage.

Increased productivity

The PAT series improves battery testing productivity. The single-use concept avoids the effort related to cleaning and disassembling the PAT-Cores. When used with a PAT-Tester-i-16 potentiostat, cell wiring is not required – simply insert the cell and start the test.

Moreover, the PAT-Tester-i-16 comes with an integrated, software-controlled temperature chamber (+10 to +80 °C), so there is no need for additional devices. These features increase the productivity of battery testing and facilitate high-throughput testing.

The PAT-Core components in detail

Upper plunger

By default, the upper plunger serves as the negative current collector. The given size fits for any thickness of the upper electrode up to 800 μm . The plungers are available in Stainless Steel (ss), Al and Cu, and as a special version made of PEEK polymer. The PEEK plungers are used in combination with a disc-shaped metal foil as the current collector. Many different metals are available including Au, Pt and Ni.

For use with printed electrodes, a special slotted current collector foil made of stainless steel is available as well. It can be used in combination with all available plungers.

| Upper plunger | |||

|---|---|---|---|

| Item name | Type | Order no. | |

| Upper plunger (Stainless steel) | Reusable | ECC1-01-0026-C Buy online |

| Upper plunger (Nickel) | Reusable | ECC1-01-0026-M Buy online |

| Upper plunger (PEEK) with upper feed wire (Au) and disk spring (Au) | Reusable | ECC1-01-0065-A Buy online |

| Upper plunger (Al) | Single-use | ECC1-01-0026-B Buy online |

| Upper plunger (Cu) | Single-use | ECC1-01-0026-A Buy online |

Insulation sleeves

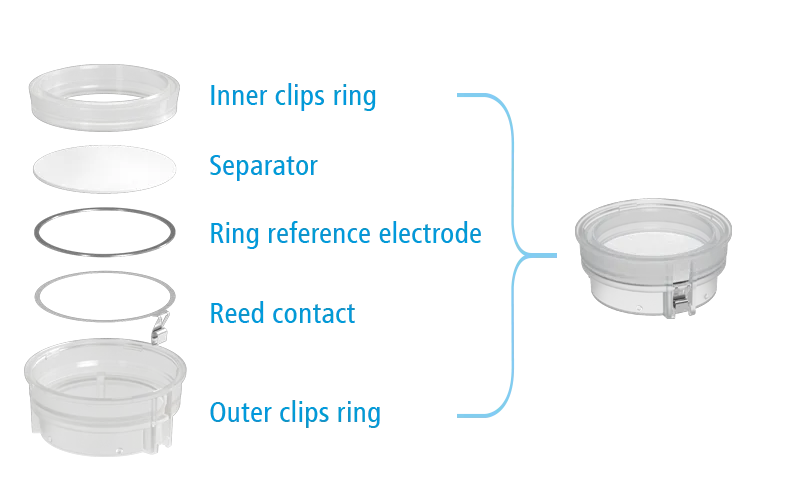

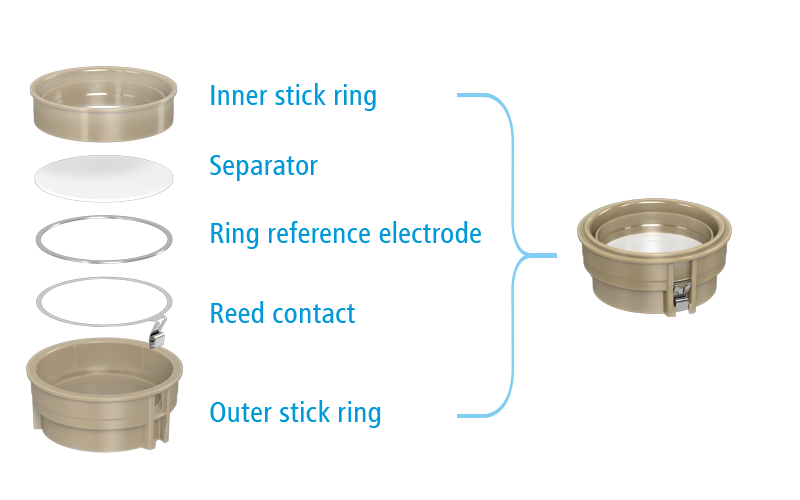

Insulation sleeves are available in the materials polyproplyen (PP) and PEEK. The inner and outer ring are clipsed (PP) or sticked (PEEK) together with a separator or separator -like material (such as a solid state electrolyte) in between. For three -electrode tests, a reference ring can be additionally mounted into the insulation sleeve. An additional reed contact serves as the electrical contact for the reference ring. Different reference ring materials are available including lithium metal and LTO.

1. Insulation sleeve (PP) for single-use

The variant made of polypropylene is a single-use item with built-in separator, ring reference and reed contact. The single-use concept lowers lead times in the lab and is the perfect choice for high-throughput testing.

2. Insulation sleeve (PEEK), reusable

The PEEK variant of the insulation sleeve is reusable and optimal for higher temperatures (up to 200 °C). It is assembled before each testing, so you can modify its components easily. It is the right choice for small-scale testing and the more unusual ideas.

Insulation sleeves may be ordered readily assembled (PP) or for self -assembly (PP or PEEK). When assembling the insulation sleeve yourself, please use separator circles of 21.6 mm diameter. All parts except the PEEK rings are for single -use.

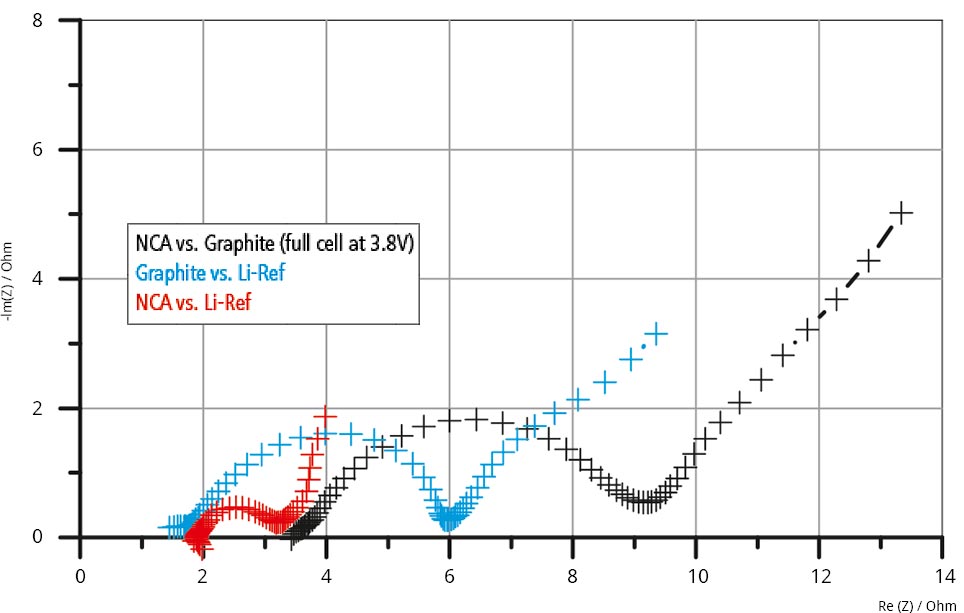

As a standard, we offer three different types of separators: a double-layered separator comprised of a 180 µm thick nonvowen PP cloth (Freudenberg FS 2226 E) and a 38 µm thick microporous UHMW-PE membrane (Lydall Solupor 5P09B), a 260µm borosilicate glass fiber separator (Whatman GF/A), and a 25µm nonwoven polyester separator pasted with Al2O3 (Freudenberg Viledon FS 3005-25). Other separators and customized solutions are available on request.

Separator comparison:

| Separator | FS-5P (Freudenberg Viledon FS 2226E + Gore Heerlen Solupor 5P09B) | Whatman GF/A | Celgard QT17P2HX |

| Thickness | 220µm | 260µm | 16.5µm |

| Material | PP fiber/PE membrane | Borosilicate glass fiber | PVDF/PP/PE/PP/PVDF |

| Porosity | FS: 67%/ 5P: 86% | 91% | 54% |

| Wettability | Good | Excellent | Good |

| Resistance to dendrites | Good | Modest | Good |

| Ability for full cell cycle tests | Good | Good | Good |

| Ability for half cell cycle tests (vs. Li) | Good | Good | Modest |

| Ability for full cell EIS | Excellent | Excellent | Excellent |

| Ability for individual electrode EIS | Modest | Good | Modest |

| Order no (Insulation sleeve (PP) with Li reference) | ECC1-00-0210-V/X | ECC1-00-0210-O/X | ECC1-00-0420-O/X |

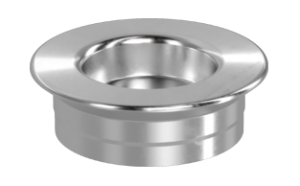

Lower plunger

By default, the lower plunger serves as the positive current collector . The choice of materials is the same as for the upper plunger, however, the lower plunger comes in different sizes (height numbers) to account for different thicknesses of the lower electrode and the separator. Available height numbers range between 50 and 800 in steps of 50. The proper plunger height must be chosen to ensure that the pre -assembled separator is not excessively bent during assembly of the PAT -Core. The proper height number depends on both the thickness of the lower electrode and the thickness of the built -in separator. Please note that the height number starts with a zero point offset of 50. The height number does not refer directly to the height of the lower electrode in μm.

Our configurator can help you to determine the proper lower plunger for your battery test: