ECC-Std

Electrochemical test cell for two-electrode battery testing

Make the move to the PAT-Cell

Our PAT series test cells offer many advantages over their ECC predecessors:

No more drying and cleaning of cell components

Superior half-cell impedance measurements due to the ring-shaped reference electrode

Improved sealing concept for much better long-term stability (See sample test here)

Easy-to-use cableless design. Just insert it into a PAT battery tester and start your measurement.

Make the move to the PAT-Cell

Our PAT series test cells offer many advantages over their ECC predecessors:

No more drying and cleaning of cell components

Superior half-cell impedance measurements due to the ring-shaped reference electrode

Improved sealing concept for much better long-term stability (See sample test here)

Easy-to-use cableless design. Just insert it into a PAT battery tester and start your measurement.

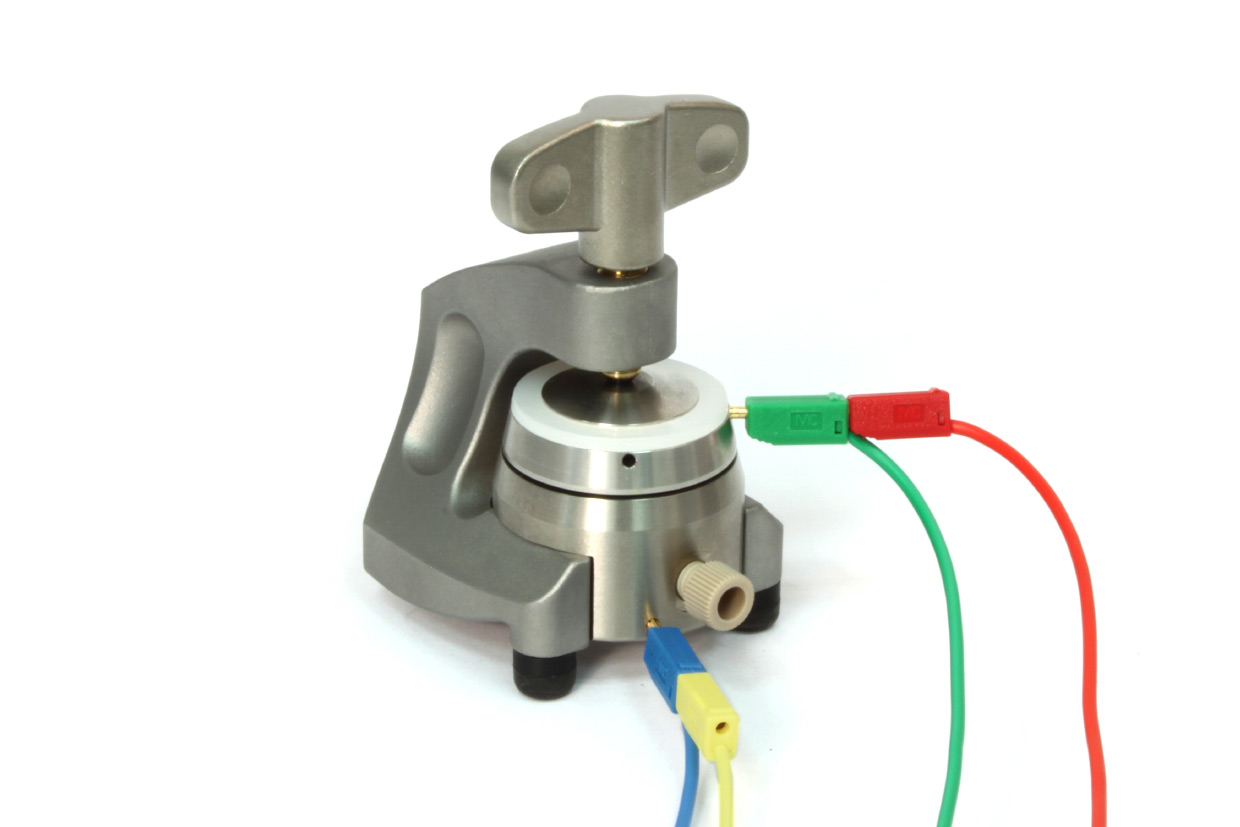

The ECC-Std electrochemical cell is dedicated to the characterization of aprotic battery and capacitor systems in two-electrode configuration. The most typical application is the characterization of a lithium-ion battery electrode (anode or cathode) against a lithium metal counter electrode. A re-fitting kit is available to use the ECC-Std cell in combination with a reference electrode, thereby converting the ECC-Std into the ECC-Ref test cell.

Cell parts that come in contact with the electrolyte are made of stainless steel and PEEK and can thus withstand all common aprotic organic electrolytes used in lithium-ion battery and aprotic supercapacitor technology.

ECC-Std Overview

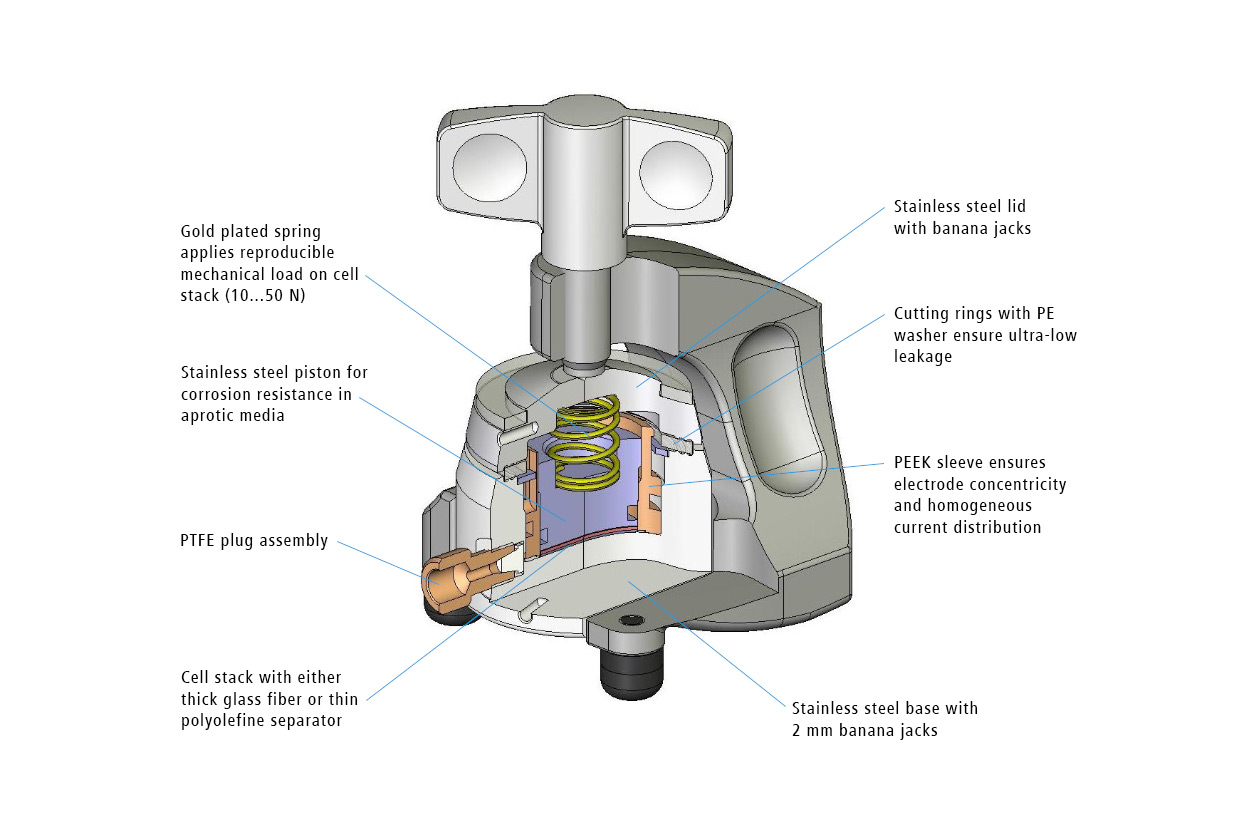

High precision 18 mm diameter sandwich geometry with <0.1 mm electrode concentricity

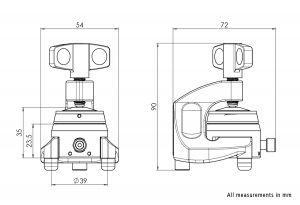

Adjustable, reproducible and homogeneous mechanical pressure on electrodes Reliable low leakage sealing with PE washers Easy and reliable electrolyte filling upon assembly Fast assembly and dismantling and easy cleaning of cell components Electrodes are easily accessible for post-mortem analysis Reusable cell components except for PE sealing Materials in media contact are stainless steel 1.4404 and PEEK Small and defined electrolyte volume down to 0.05 cm³ due to minimized dead volume Materials in media contact are stainless steel and PEEK Special materials/ solutions on request Optionally available: Std to Ref upgrade kit| Height | 90 mm |

| Width | 54 mm |

| Depth | 72 mm |

| Weight | 0.6 kg |

| Temperature resistance: | -40 to +80 °C (150 °C)* |

| Electrode diameter | 18 mm |

| Electrolyte volume min | 0.1 ml |

| *with optional Heat Resistance Set ECC1-01-0040-A |

| ECC-Std User Manual | |

| Release | 3.81 | |

| Type | ||

| Size | 1.0 MB | |

| Download |

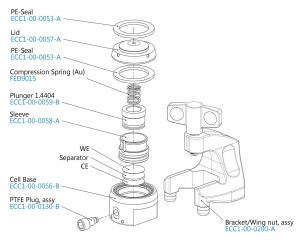

| Component | Order no. |

| ECC-Std test cell | |

| PE-Seal (10 pcs.) | ECC1-00-0053-A/X |

| Sleeve Removing Tool | ECC1-00-0092-A |

| Glass fiber separator 18 mm x 1.55 mm (10 pcs.) | ECC1-01-0012-C/X |

| Separator (Celgard 2325) 24 mm x 0.025 mm (10 pcs.) | ECC1-01-0022-D/X |

| Package content | |

| Heat Resistance Set (ECC-Series) | ECC1-01-0040-A |

| ECC-Series Cell Cable Set HT | ECE1-00-0037-B |

| HT Foot (heat resistant), (3 pcs) | ECC1-00-0065-B |

| PTFE Seal (ECC Series), (10 pcs) | ECC1-00-0053-B/X |

Gallery

Recommended Tools

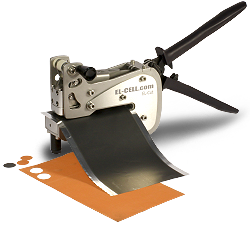

EL-Cut

High precision cutting pliers to eliminate torn and chipped electrode edges. Recommended diameter size for use with the ECC-Std is 18 mm.