PAT-Cell

Battery Test Cell for 2- and 3-Electrode Measurements

PAT-Cell

PAT-Cell M

PAT-Core

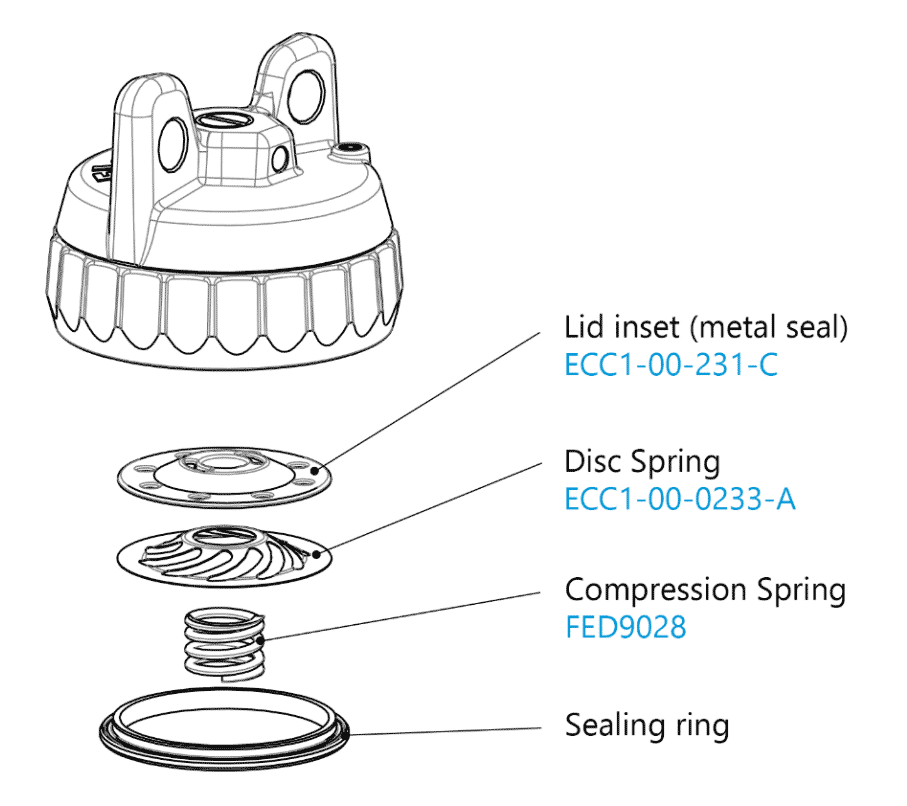

Metal Lid Seal

PAT-Button

Typical Use Cases

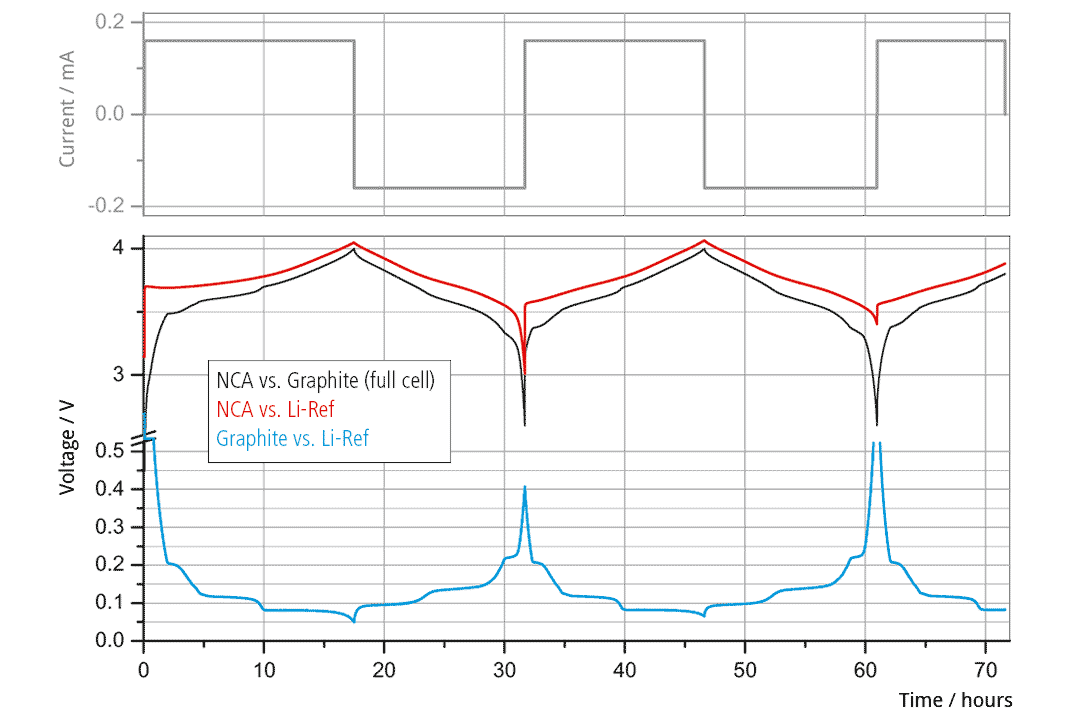

- Electrochemical Cycling with 2- or 3 Electrodes

- High-Throughput and Long-term Testing

- Aprotic and Aqueous Electrolytes

Key Features

PAT-Core for modular cell stack configuration

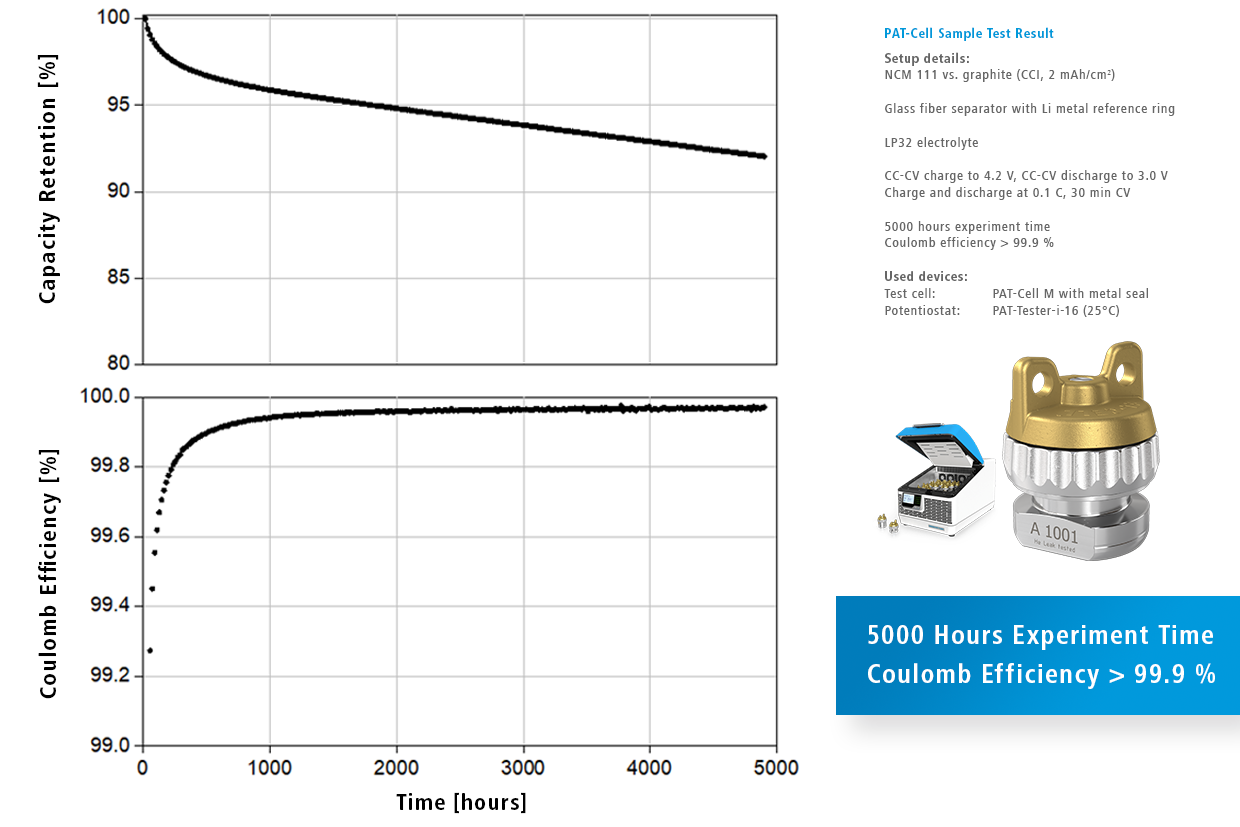

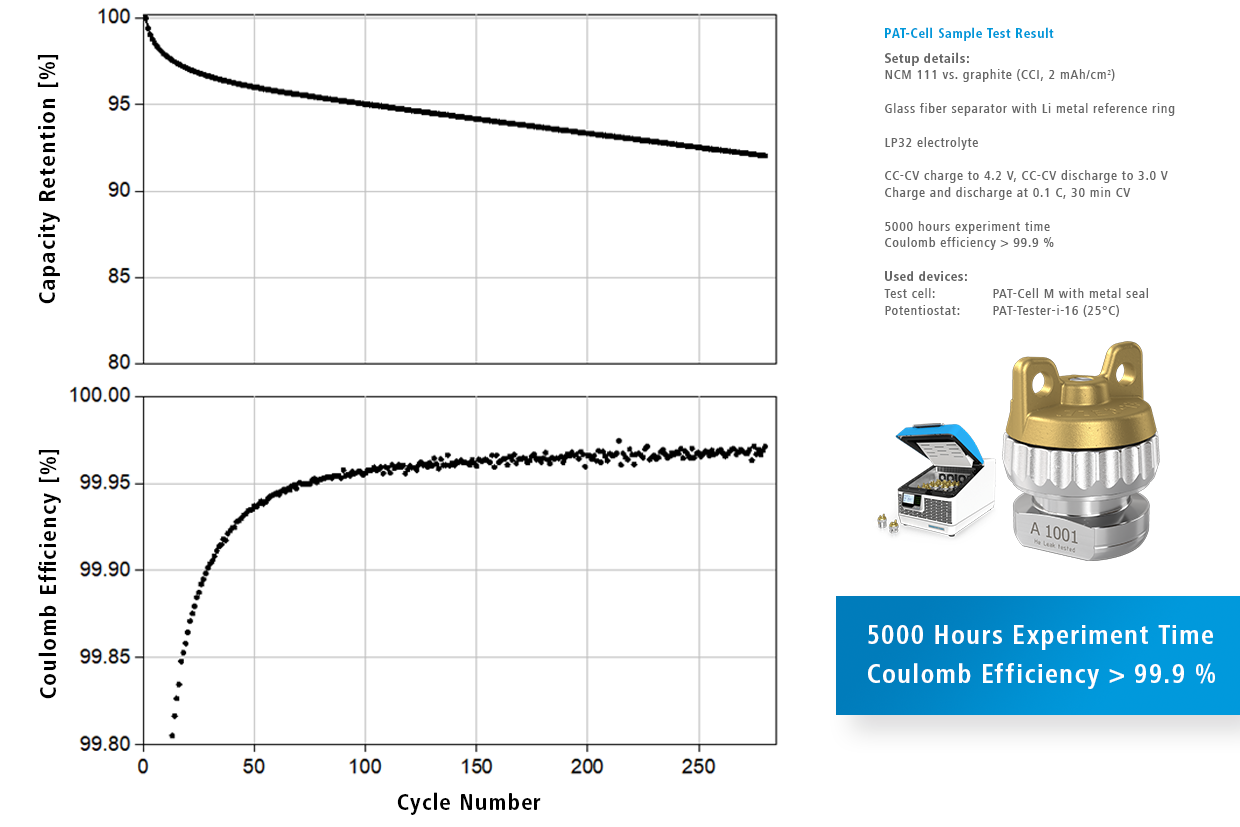

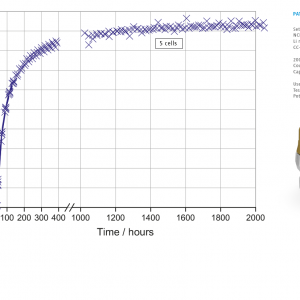

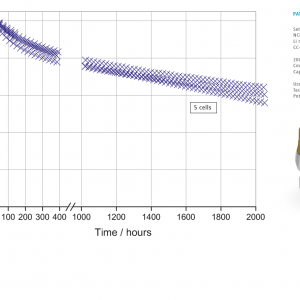

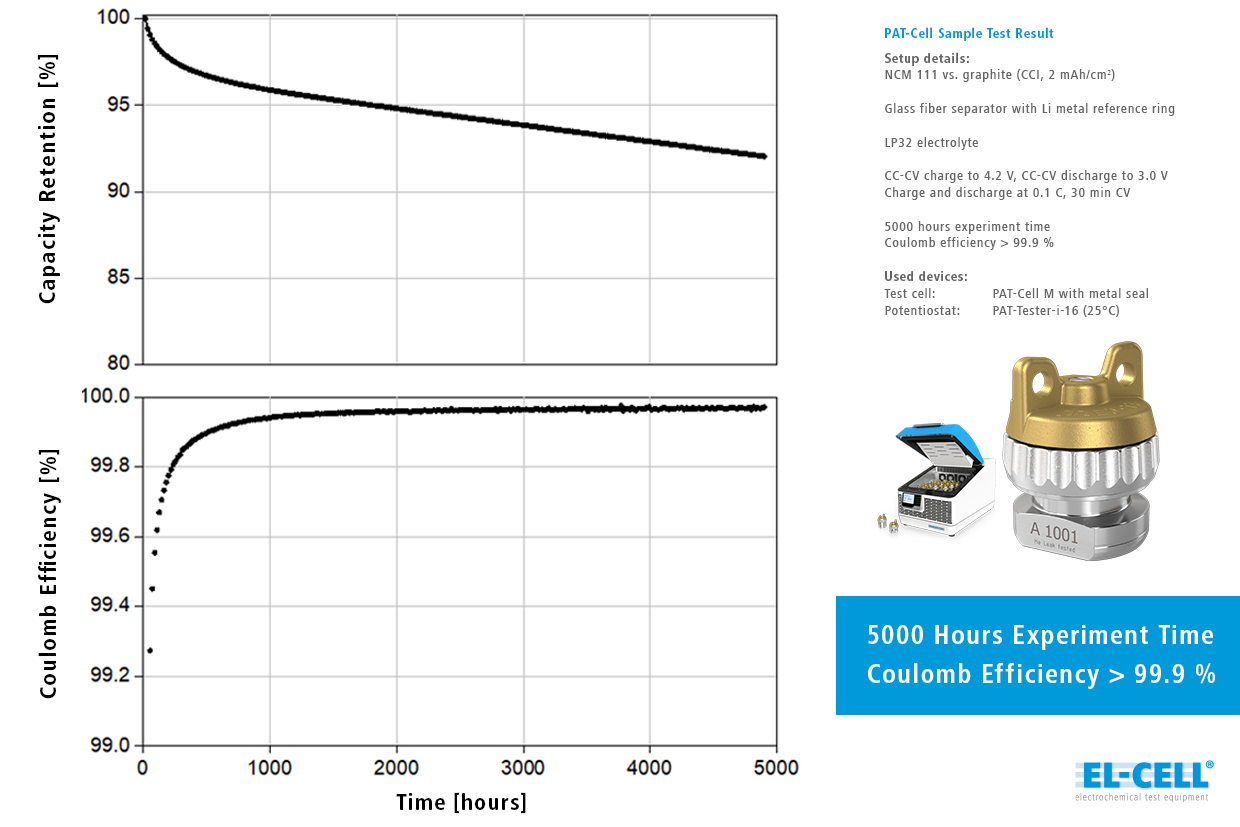

For long-term testing ( > 5000 hrs) with two or three electrodes

Cableless cell design for easy handling and fast assembly

Compatible with aprotic as well as aqueous electrochemistry

Interchangeable lid springs for easy force adjustment

Optimzied lid for use with metal seals (PAT-Cell M)

PAT-Button for automatic cell identification in EL-Software

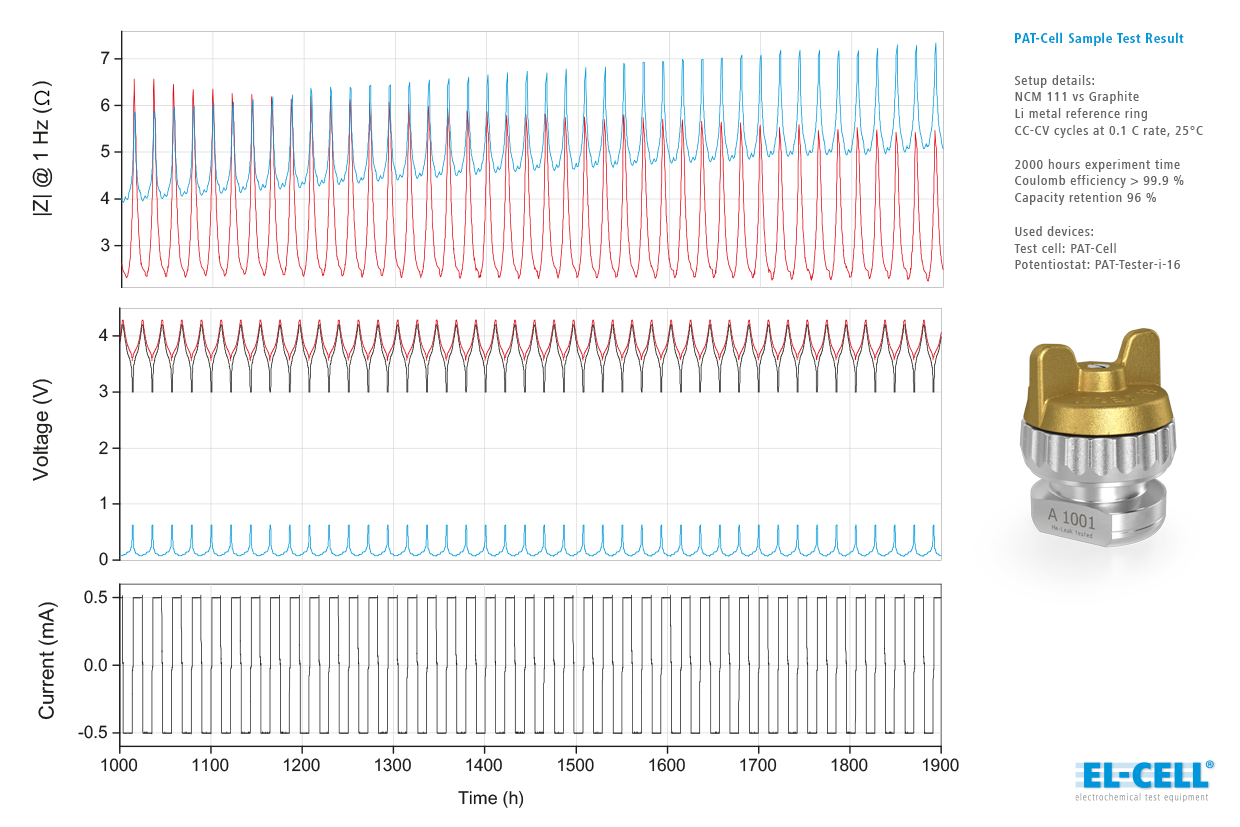

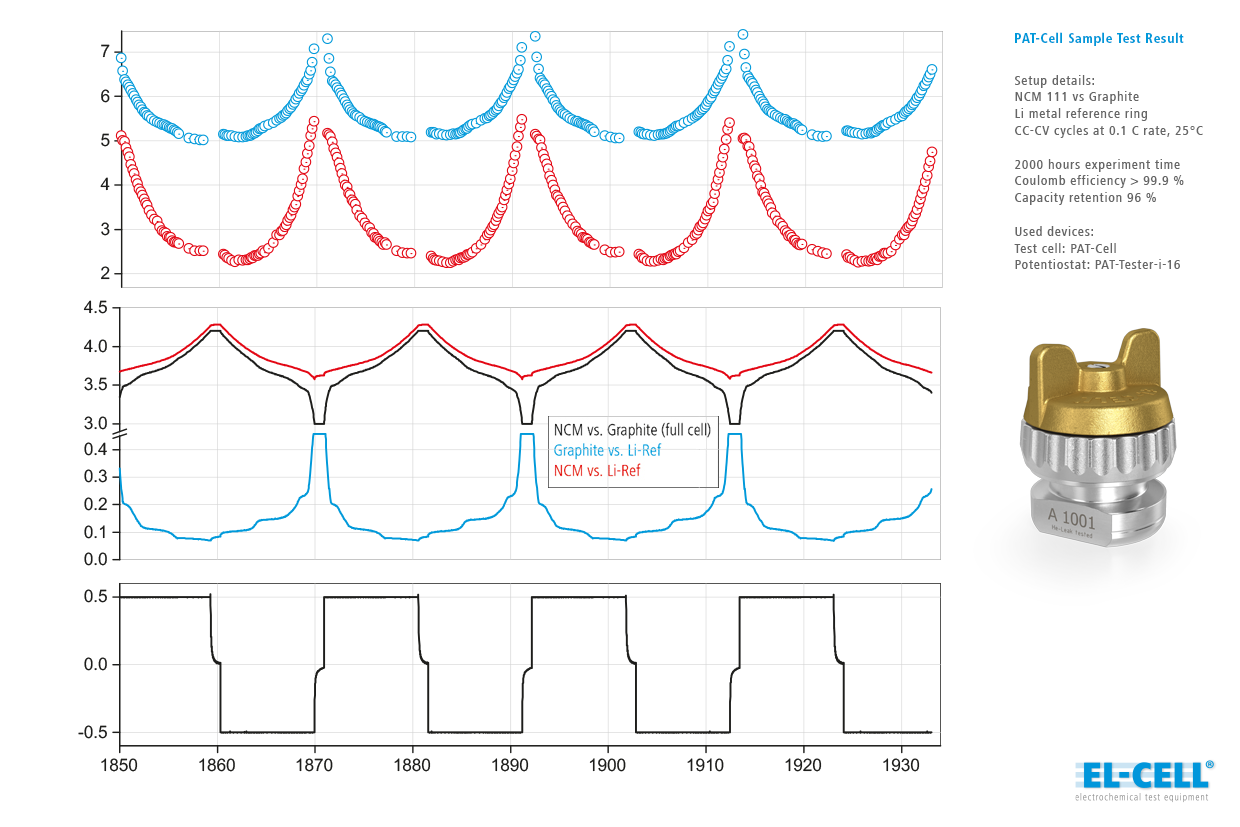

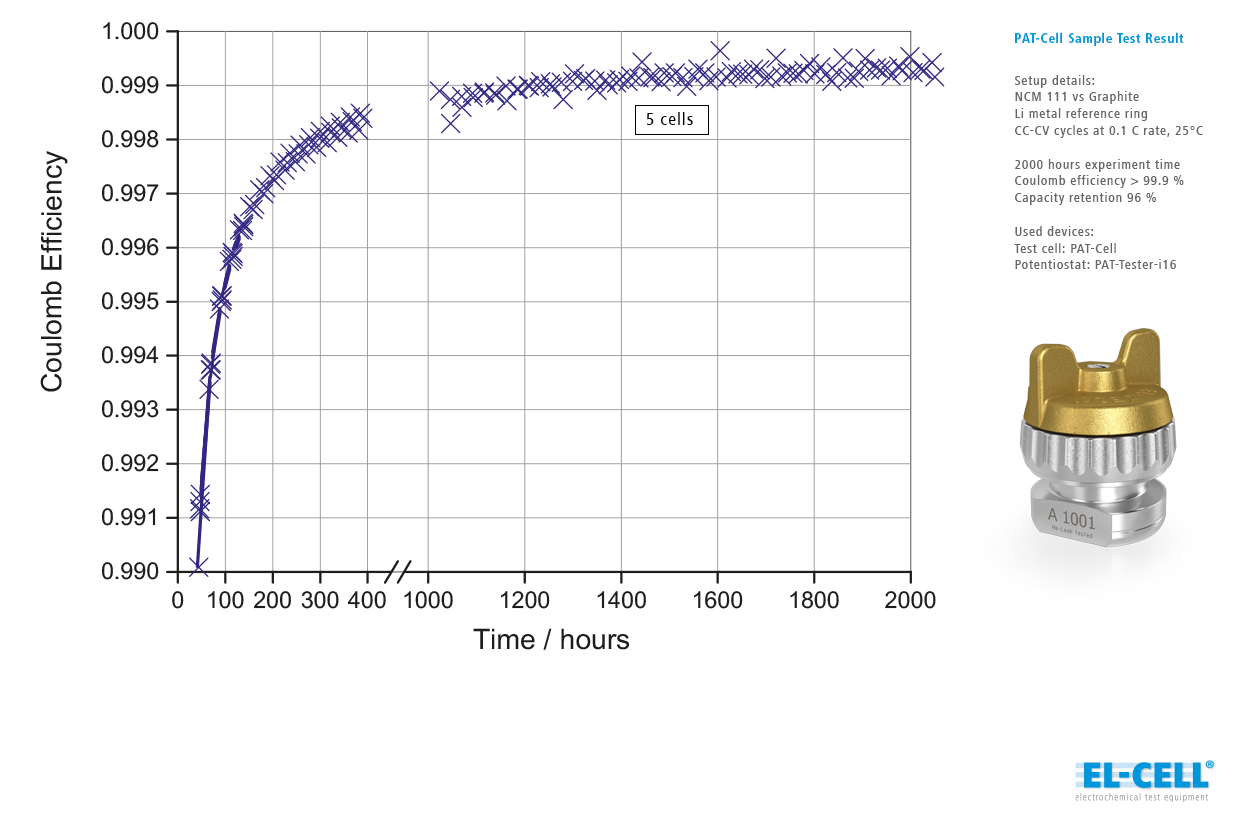

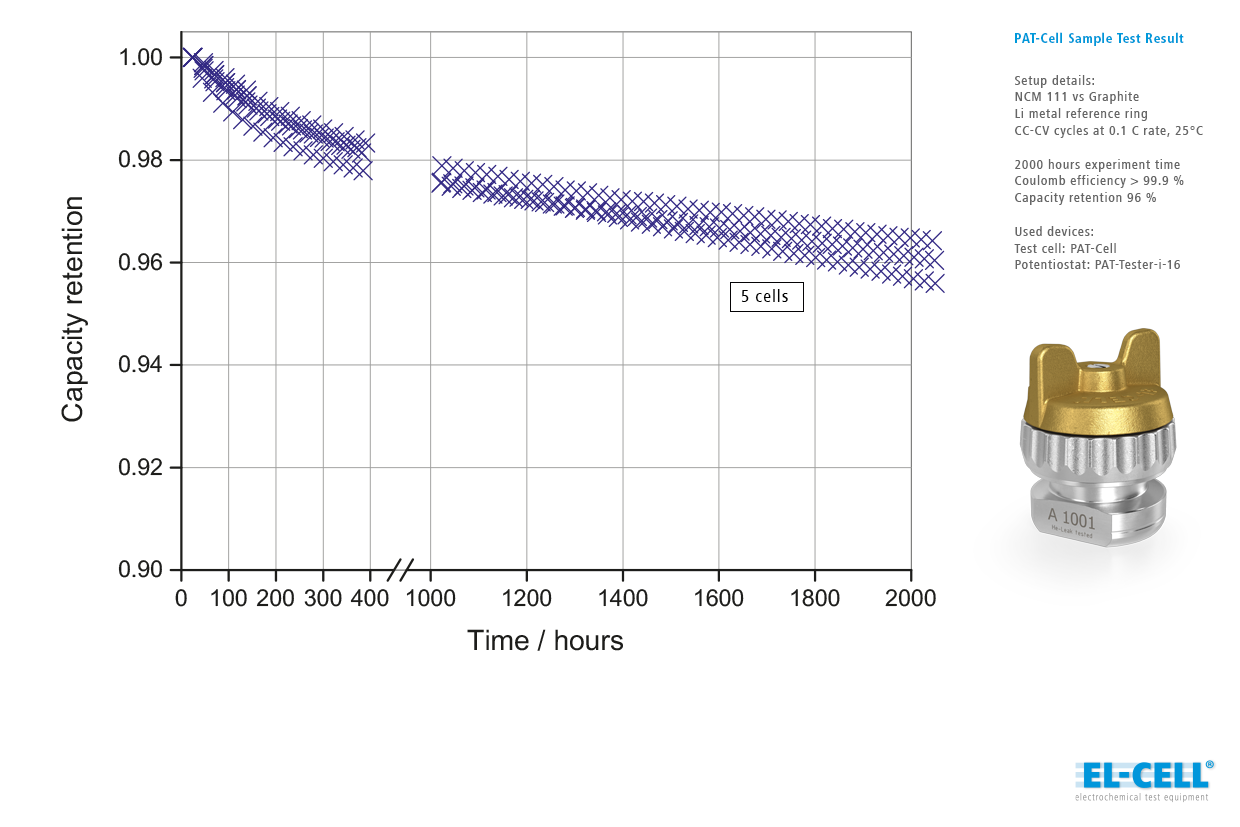

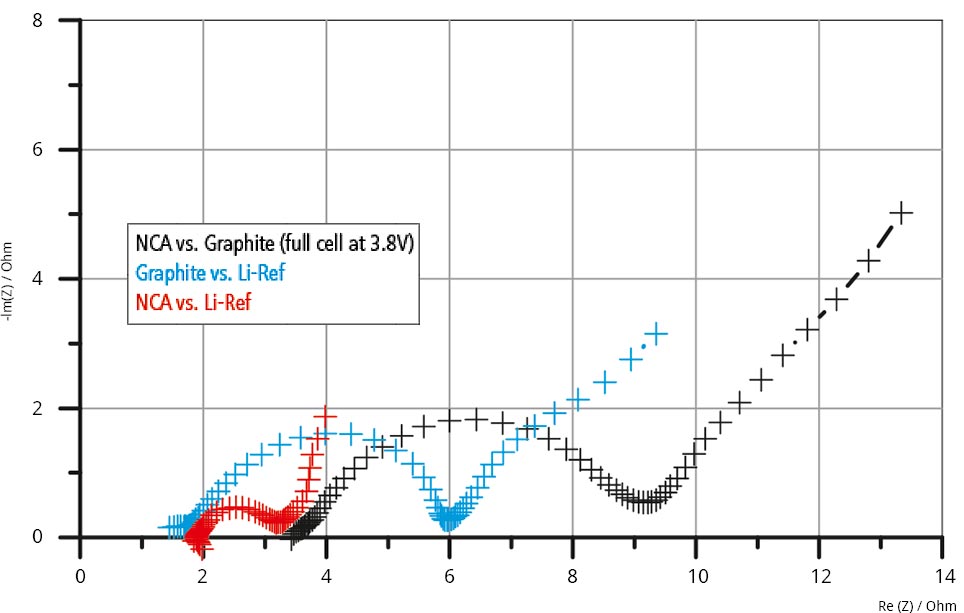

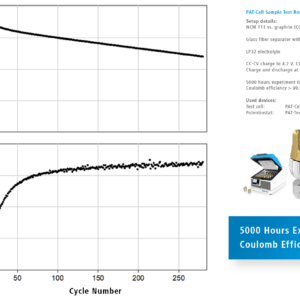

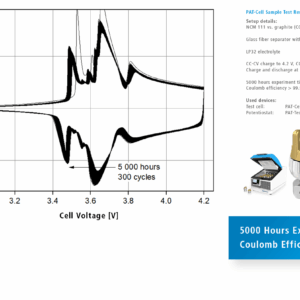

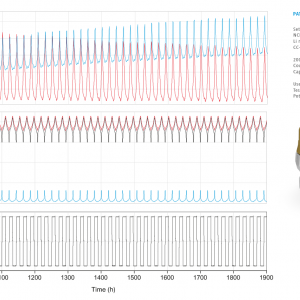

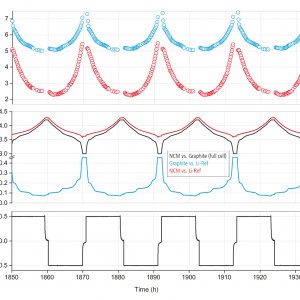

Sample Test Results

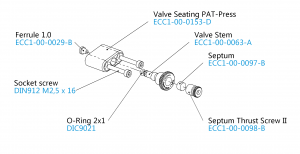

Product Description

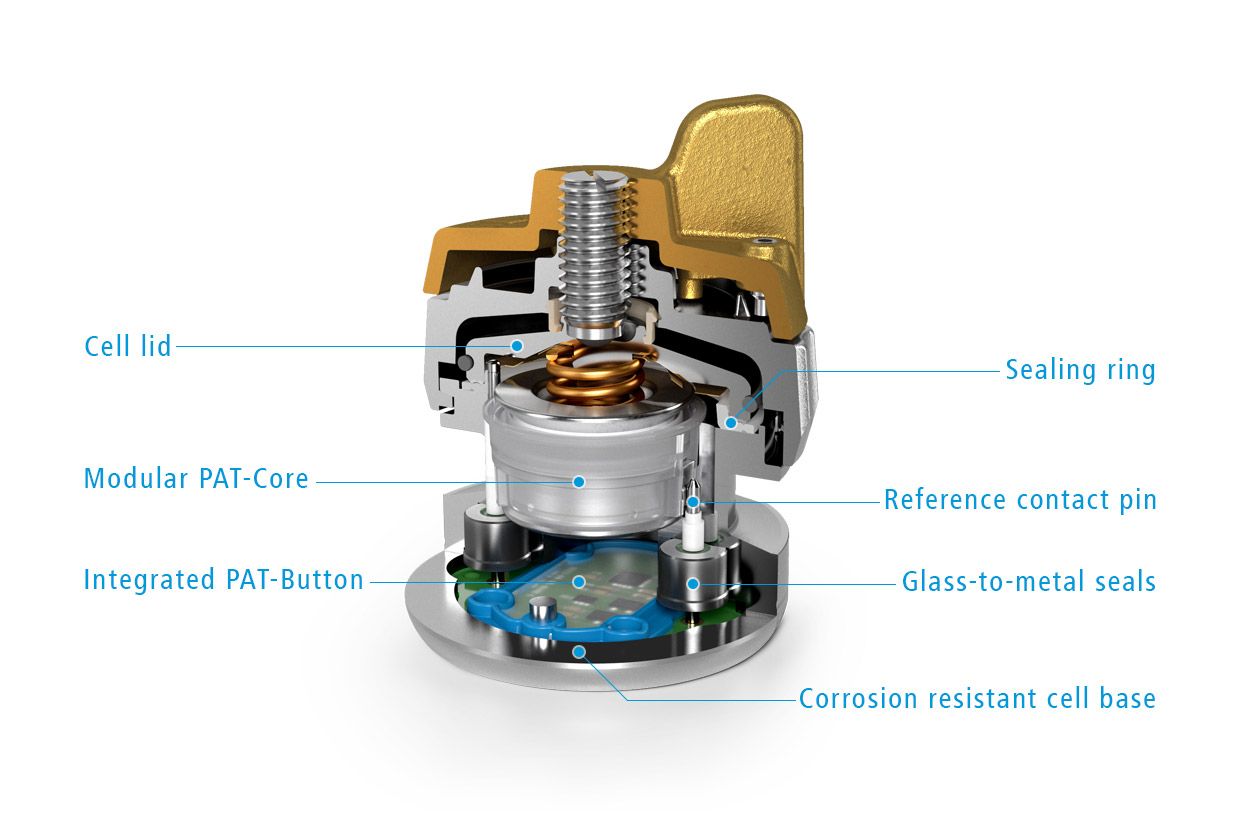

The PAT-Cell is designed for 2- and 3-electrode measurements on battery materials. Utilizing the modular PAT-Core components for building the cell stack, it is adaptable for various testing purposes. Depending on the specific application, different sealing materials such as polypropylene (PP), polytetrafluoroethylene (PTFE), or aluminum can be used in the PAT-Cell, ensuring stable measurements over long durations, even thousands of hours.

The PAT-Cell M variant is prepared for use with metal seals as standard, while the regular PAT-Cell can be easily retrofitted.. There is no wiring involved; the cell can be directly inserted into a PAT battery tester or connected to any commercially available battery tester or potentiostat via a PAT docking station. This speeds up the experiment setup and reduces signal noise.

Ease of use is enhanced by several features, including the integrated PAT-Button. This electronic memory, located at the bottom of the cell, allows for automatic cell recognition when the cell is inserted into a PAT battery tester. The PAT-Cell is perfectly suited for both automated high-throughput scenarios and small-scale testing series.

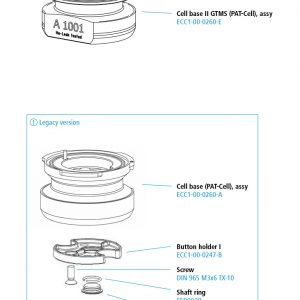

Product Variants

Specifications

| Features of the PAT-Cell | |

| Docking / Test station | Charge/Discharge/Impedance |

| PAT-Clamp-1 | |

| PAT-Stand-1 | |

| PAT-Stand-1 U | |

| PAT-Stand-4 | |

| PAT-Stand-16 | |

| PAT-Chamber-16 | |

| PAT-Tester-x-8 | |

| PAT-Tester-i-16 | |

| PAT-Heater-4 |

Documentation

Frequently Asked Questions

The compatible cell lid for metal seals (Item name: Screw cap insulated (PAT)) can be recognized by two features. It has two holes on the top and a white or black inset made of PPS in the lid, which serves as insulation.

As the two holes can also be found on older cell lids without insulation, you should always check whether the inset is present. Non-compatible cell lids have no inset at all.

Yes, our PAT series test cells can be operated on any common battery tester or potentiostat using a PAT docking station. Most docking stations are connected via conventional 4 mm banana plugs. The PAT-Stand-16 and PAT-Chamber-16 are offered with fixed open-ended cables. Cell cables with custom connectors to connect these units to a specific battery tester are available on request at extra cost.

Yes, this is possible. The cell bases of all current cells of the PAT series, except the PAT-Cell-Twin-Ref, are made of corrosion-resistant steel (1.4404) and are therefore generally suitable for use with aqueous electrolytes. Please note that this applies to the PAT-Cell only for models manufactured from September 2019 (revision no.4) and PAT-Cell-Press manufactured from June 2019 (revision no. 3).

Battery Test Cell for 2- and 3-Electrode Measurements

The PAT-Cell is designed for 2- and 3-electrode measurements on battery materials. Utilizing the modular PAT-Core components for building the cell stack, it is adaptable for various testing purposes. Depending on the specific application, different sealing materials such as polypropylene (PP), polytetrafluoroethylene (PTFE), or aluminum can be used in the PAT-Cell, ensuring stable measurements over long durations, even thousands of hours.

The PAT-Cell M variant is prepared for use with metal seals as standard, while the regular PAT-Cell can be easily retrofitted.. There is no wiring involved; the cell can be directly inserted into a PAT battery tester or connected to any commercially available battery tester or potentiostat via a PAT docking station. This speeds up the experiment setup and reduces signal noise.

Ease of use is enhanced by several features, including the integrated PAT-Button. This electronic memory, located at the bottom of the cell, allows for automatic cell recognition when the cell is inserted into a PAT battery tester. The PAT-Cell is perfectly suited for both automated high-throughput scenarios and small-scale testing series.

PAT-Cell Overview

- Electrochemical Cycling with 2- or 3 Electrodes

- High-Throughput and Long-term Testing

- Aprotic and Aqueous Electrolytes

PAT-Core for modular cell stack configuration

For long-term testing ( > 2000 hrs) with two or three electrodes Cableless cell design for easy handling and fast assembly Interchangeable lid springs for easy force adjustment Optimized lid for use with metal seals (PAT-Cell M) PAT-Button for automatic cell identification in EL-Software

PAT-Cell

The PAT-Cell is our proven 3-electrode test cell for high-throughput measurements and small series of measurements.

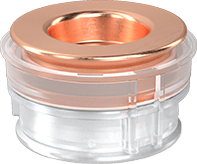

PAT-Cell M

The PAT-Cell M is equipped with an optimized cell lid, suitable for both metal and proven polymer seals. Our aluminum lid seals meet the highest demands on cell tightness and are particularly suitable for long-term measurements.

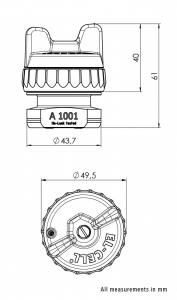

| Diameter | 49.5 mm |

| Height | 61 mm |

| Weight | 0.4 kg |

| Electrode diameter | 18 mm |

| Separator diameter | 21.6 mm |

| Operational temperature | -20 to 80° C |

Compatible Potentiostats/PAT docking stations

| Features of the PAT-Cell | |

| Docking / Test station | Charge/Discharge/Impedance |

| PAT-Clamp-1 | |

| PAT-Stand-1 | |

| PAT-Stand-1 U | |

| PAT-Stand-4 | |

| PAT-Stand-16 | |

| PAT-Chamber-16 | |

| PAT-Tester-x-8 | |

| PAT-Tester-i-16 | |

| PAT-Heater-4 |

How can I identify whether my PAT-Cell is suitable for use with metal seals?

The compatible cell lid for metal seals (Item name: Screw cap insulated (PAT)) can be recognized by two features. It has two holes on the top and a white or black inset made of PPS in the lid, which serves as insulation.

As the two holes can also be found on older cell lids without insulation, you should always check whether the inset is present. Non-compatible cell lids have no inset at all.

Can I connect PAT-Cells respectively the PAT docking stations to any battery tester or potentiostat?

Yes, our PAT series test cells can be operated on any common battery tester or potentiostat using a PAT docking station. Most docking stations are connected via conventional 4 mm banana plugs. The PAT-Stand-16 and PAT-Chamber-16 are offered with fixed open-ended cables. Cell cables with custom connectors to connect these units to a specific battery tester are available on request at extra cost.

Can I use the PAT-Cells for experiments with aqueous electrolyte?

Yes, this is possible. The cell bases of all current cells of the PAT series, except the PAT-Cell-Twin-Ref, are made of corrosion-resistant steel (1.4404) and are therefore generally suitable for use with aqueous electrolytes. Please note that this applies to the PAT-Cell only for models manufactured from September 2019 (revision no.4) and PAT-Cell-Press manufactured from June 2019 (revision no. 3).

Please note that not all combinations may be well suited for your testing setup. As a guide you can use our sample setups that cover the most common applications.

Accessories, Consumables & Spare Parts

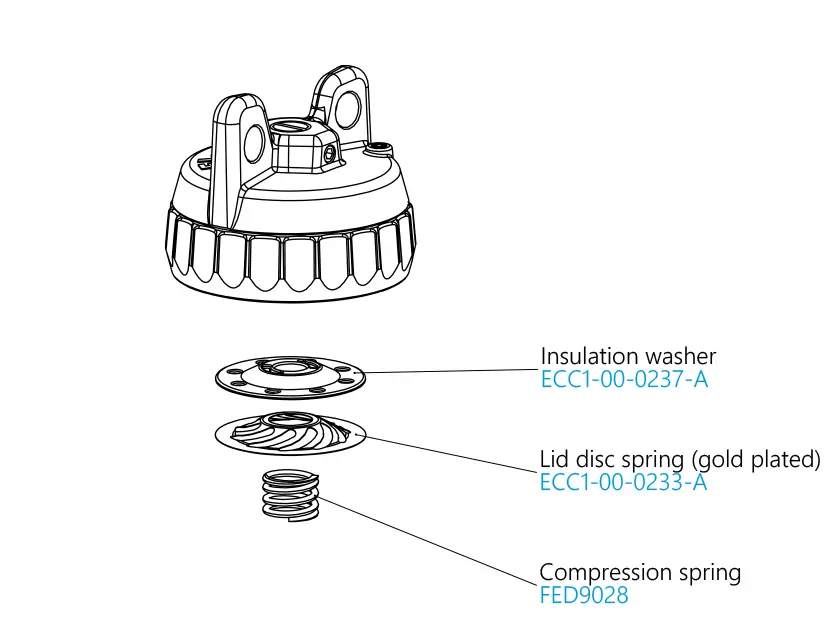

Screw cap insulated (PAT) (Order no.: ECC1-00-0236-D )

This optio nal screw cap makes it possible to use metal sealing rings made of aluminum in the PAT-Cell. Metal seals offer the highest tightness against the ambient atmosphere and are best suited for stable long-term measurements. The cap is fully compatible with all other sealing materials for the PAT series. Please note: A torque wrench is needed to ensure the correct installation when using metal seals. We strongly recommend using our Metal seal mounting kit for this purpose.

nal screw cap makes it possible to use metal sealing rings made of aluminum in the PAT-Cell. Metal seals offer the highest tightness against the ambient atmosphere and are best suited for stable long-term measurements. The cap is fully compatible with all other sealing materials for the PAT series. Please note: A torque wrench is needed to ensure the correct installation when using metal seals. We strongly recommend using our Metal seal mounting kit for this purpose.

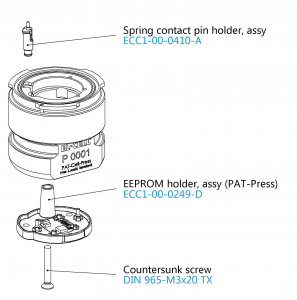

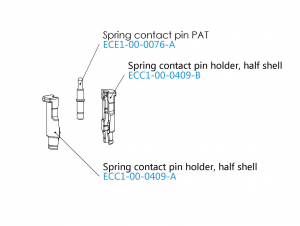

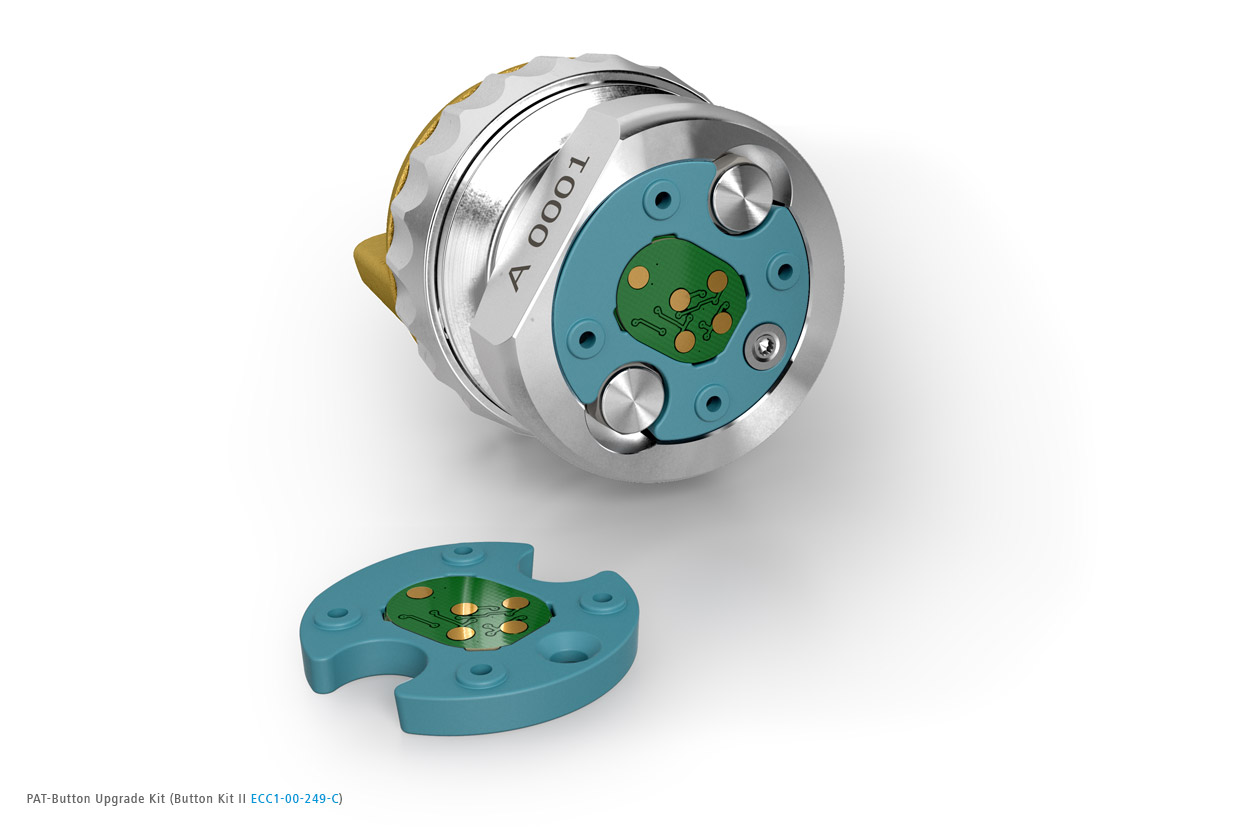

PAT-Button Upgrade Kit for PAT-Cell (Button Kit II, Order no.: ECC1-00-0249-C )

Benefit from the automatic cell recognition in our PAT battery testers. If you have older PAT-Cells without a built-in PAT button, you can upgrade them with this kit. It contains an electronic memory chip on which the cell ID and cell type is stored. When inserted into a PAT battery tester, the PAT-Cell is automatically detected by its electronic signature and displayed in EL-Software. In this way, you always have an overview of your test cells. Notes on paper or directly on the cell are therefore superfluous.

Benefit from the automatic cell recognition in our PAT battery testers. If you have older PAT-Cells without a built-in PAT button, you can upgrade them with this kit. It contains an electronic memory chip on which the cell ID and cell type is stored. When inserted into a PAT battery tester, the PAT-Cell is automatically detected by its electronic signature and displayed in EL-Software. In this way, you always have an overview of your test cells. Notes on paper or directly on the cell are therefore superfluous.

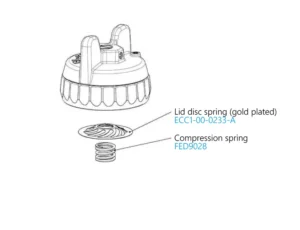

Compression spring , FED 9079

The spring force applied to the cell stack is:

- 105 N ±10% if used with aluminum lid seal *

- 115 N ±10% if used with PE lid seal *.

Compression spring , FED 9052

Compression spring , FED 9028

*Spring force values apply to an upper electrode thickness ranging from 0 to 0.8 mm. Within this range, the electrode thickness has no significant influence on the force.

Aqueous electrolytes

The PAT-Cell withstands all common aqueous electrolytes such as sulfuric acid and potassium hydroxide solution. Due to its excellent corrosion resistance, the PAT-Cell can also be used for aprotic systems beyond Li-ion. We recommend using PEEK plungers with current collector discs in gold or platinum for these applications as shown below:

Recommended PAT-Core configurations

This information can be used as a guide for building the PAT-Cell. More PAT-Core setups can be found here.

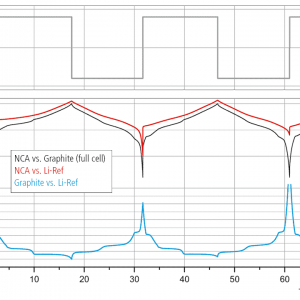

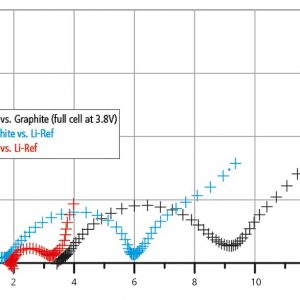

3-electrode testing with aprotic LiPF6 based electrolytes

2-electrode testing with aprotic LiPF6 based electrolytes

3-electrode testing with aprotic supercap electrolytes

*x = Height number (50 to 800). Use our configurator to determine the proper lower plunger.

**AC = Activated carbon

Recommended potentiostats

The PAT-Cell test cell is fully supported by the following potentiostats:

PAT-Tester-i-16

The PAT-Tester-i-16 integrates a temperature controlled cell chamber and docking station with a battery tester into one single instrument.

PAT-Tester-x-8

The PAT-Tester-x-8 offers maximum flexibility with up to 8 channels for small scale and special purpose testing.

Recommended tools

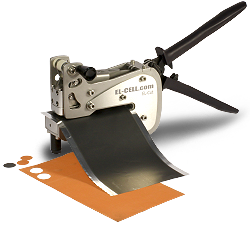

EL-Cut

High precision cutting pliers to eliminate torn and chipped electrode edges. Recommended diameter size for use with the PAT-Cell is 18 mm.

ECC-LiPunch

Punching tool for lithium foil. The recommended size for use with the PAT-Cell is 18 mm.

Related products

PAT-Tester-i-16

The PAT-Tester-i-16 integrates a temperature controlled cell chamber and docking station with a potentiostat/galvanostat into one single instrument.

PAT-Tester-x-8

Modular multi-channel potentiostat for special and small-scale testing

Product details