EL-Cut

High precision electrode cutter

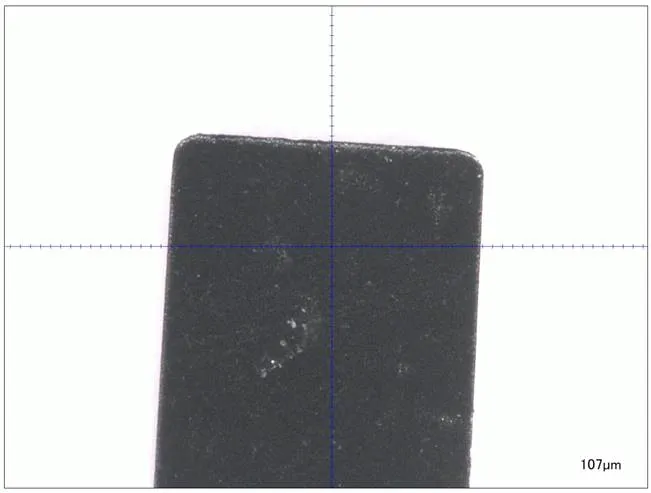

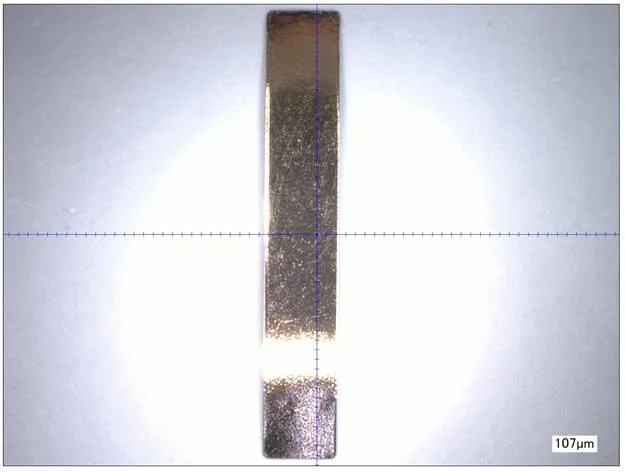

The accuracy and reproducibility of electrochemical tests depend not solely depend on the choice of materials but also on simple geometric and mechanical parameters. Proper electrode cutting is an often neglected factor. Torn and chipped electrode edges—although invisible to the bare eye—inevitably cause current inhomogeneity and are thus likely to affect experimental results. Life cycle and impedance results are especially prone to such artifacts. Electrodes cut by conventional punching (stamping) with only one punch force show chipped edges and are not plain.

The EL–Cut is a high–precision tool specifically designed to punch electrodes from coated Cu and Al foils. In contrast to conventional punching, electrodes being cut (fine blanked) by the EL-Cut are produced by three active forces in tools with a few microns of cutting clearance. The fine blanking process yields electrodes with clean cutting surfaces, free from torn or chipped edges, and nearly perfectly flat surfaces.

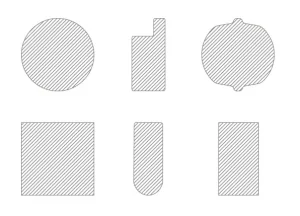

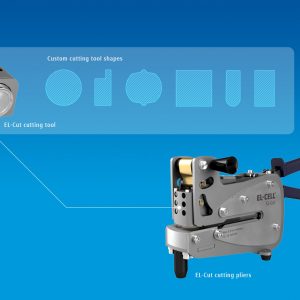

The punching tool of the EL-Cut is permanently installed and cannot be changed. The EL–Cut is available in various versions, each featuring a distinct cutting tool. The diameter of a tool can range from 5 to 40 mm. Multiple shapes, such as squares, are possible.

EL-Cut Overview

Perfectly cut electrodes

Designed for cutting electrodes coated on Al and Cu foil Cutting tools available with diameters from 6 to 40 mm (One cutting size per EL-Cut). Different shapes (e.g. squared) are available on request Low wear of the cutting tool even after prolonged use| Height | 140 mm |

| Width | 380 mm |

| Depth | 60 mm |

| Weight | approx. 2.8 kg |

| EL-Cut User Manual | |

| Release | 1.23 | |

| Type | ||

| Size | 1 MB | |

| Download |

Can you change the cutting tools of the EL-Cut?

No. The cutter of the EL-Cut must be precisely adjusted at the factory in order to achieve its high-precision cutting results. It is therefore permanently installed in the housing and cannot be changed.

Application examples for EL-Cut variants with customized cutting shapes

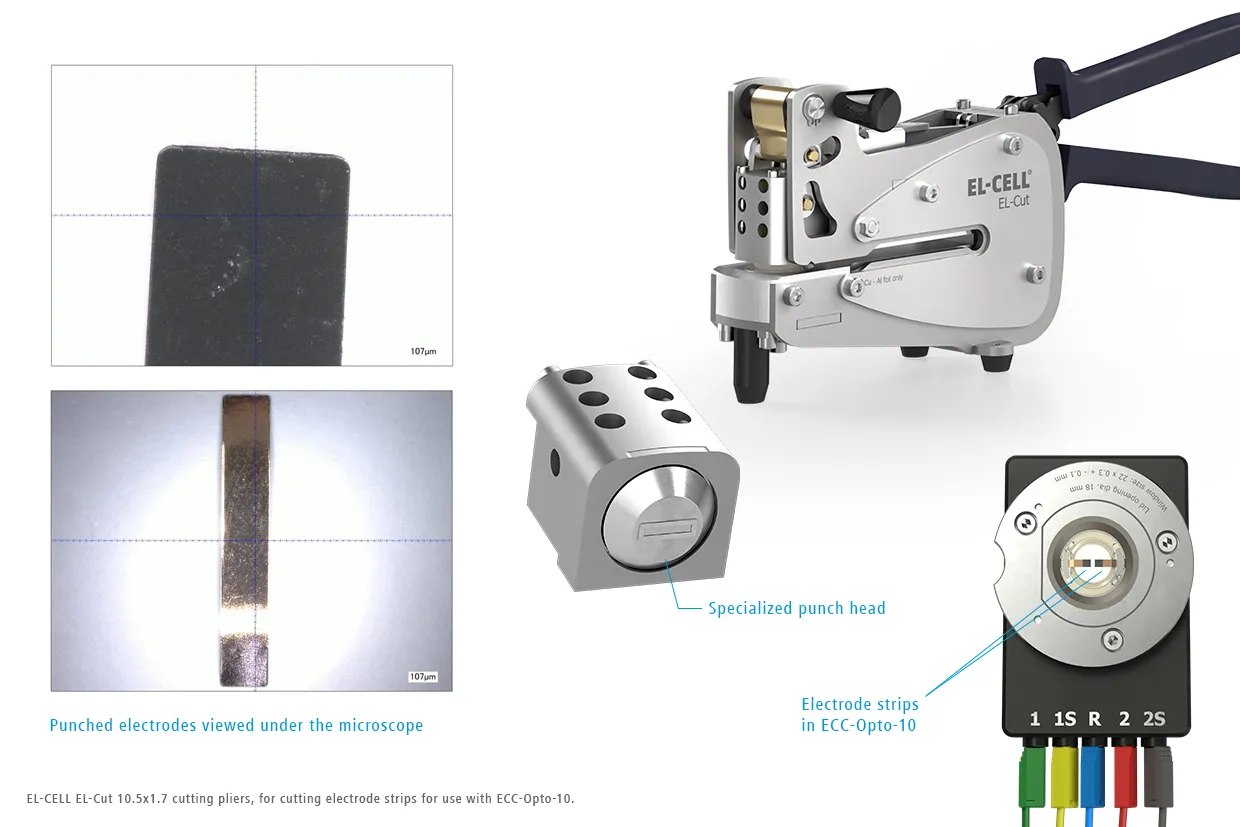

EL-Cut variant for punching electrode strips for use in ECC-Opto-10

The EL-Cut 10.5×1.7 has a cutting tool that punches out electrode strips measuring 10.5mm x 1.7mm, which are perfectly suited for the side-by-side setup of the ECC-Opto-10 and PAT-Cell-Opto-10 optical battery test cells.

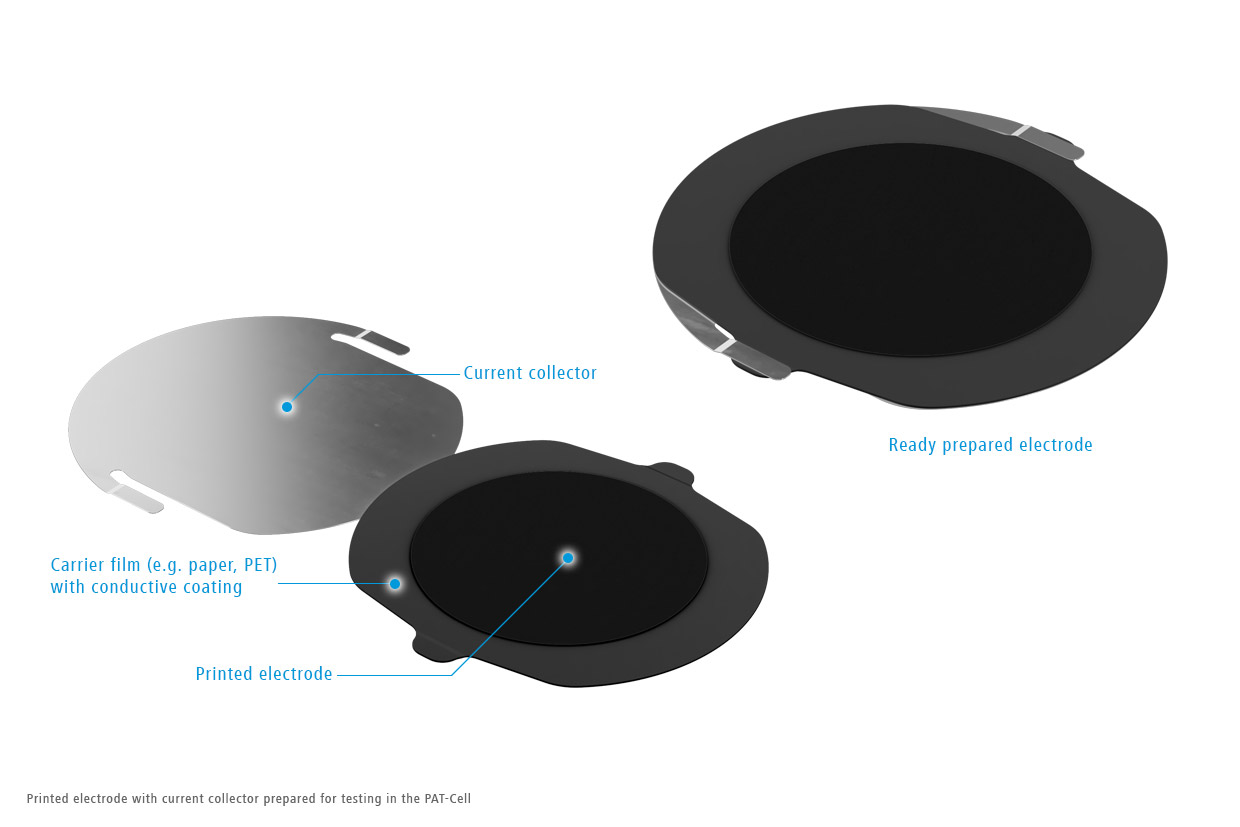

EL-Cut variant for punching printed electrodes

In order to use printed electrodes in our PAT-Cell battery test cells, the electrodes need to be punched in a specific shape. This can be easily accomplished by using the EL-Cut with customized cutting tool.

Gallery

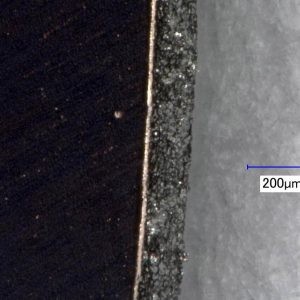

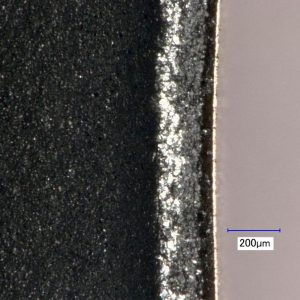

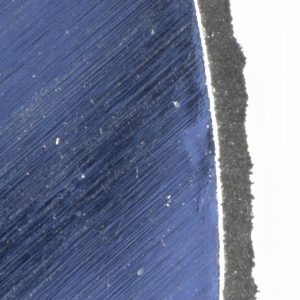

- Cutting edge CU 10 (200x magnified)

- Cutting edge CU 10 (200x magnified)

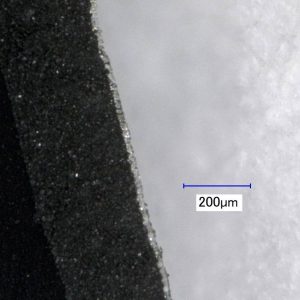

- Cutting edge of AL 20 (200x magnified)

- Cutting edge of AL 20 (200x magnified)

- EL-Cut devices with different cutter sizes (from left to right: 20×20 mm square, 18 mm disc shape and 10×10 mm square shape)

- EL-Cut devices with different cutter sizes (from left to right: 20×20 mm square, 18 mm disc shape and 10×10 mm square shape)

- Sample EL-Cut cutting tool shapes

Videos

You can download all of our videos directly from our video page.