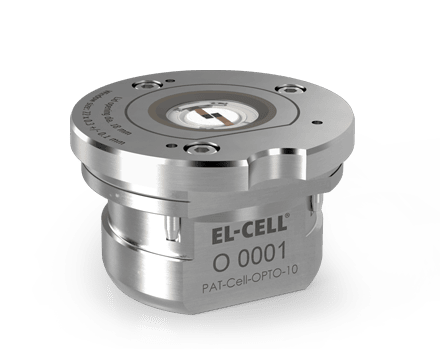

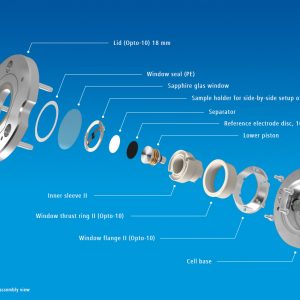

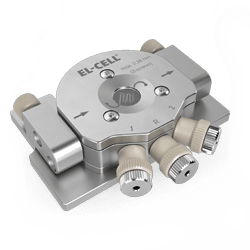

PAT-Cell-Opto-10

PAT series test cell for optical characterization in the reflective mode

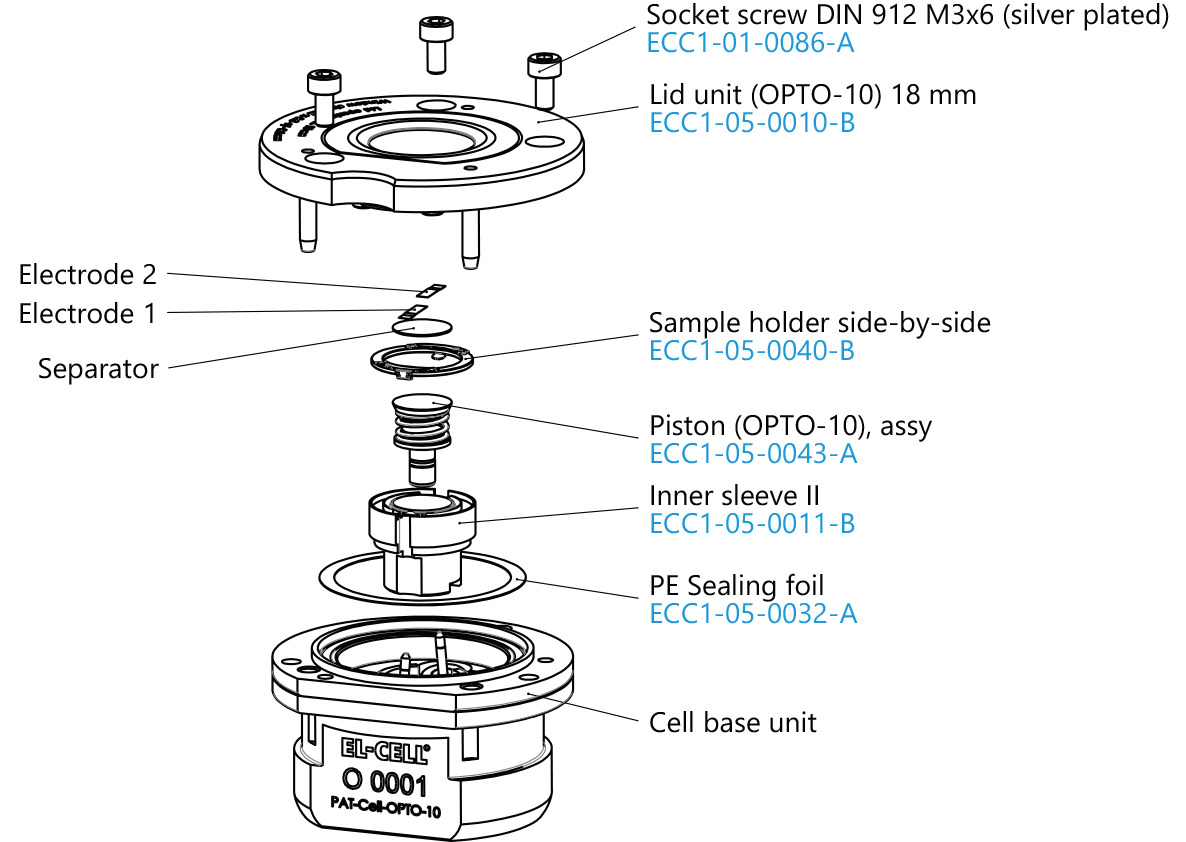

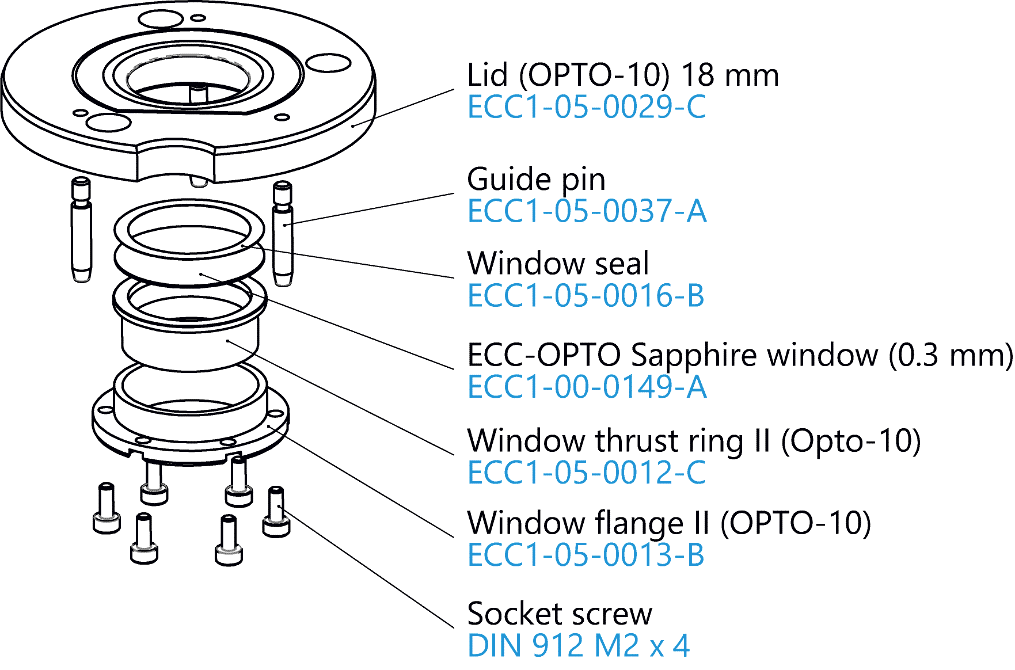

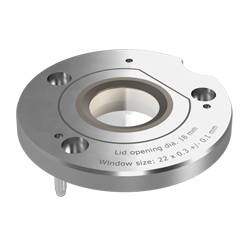

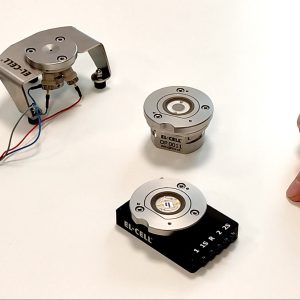

The PAT-Cell-Opto-10 is an advanced next-generation battery test cell designed for in-situ electrode characterization using methods such as light microscopy, Raman spectroscopy, or XRD in reflection mode.

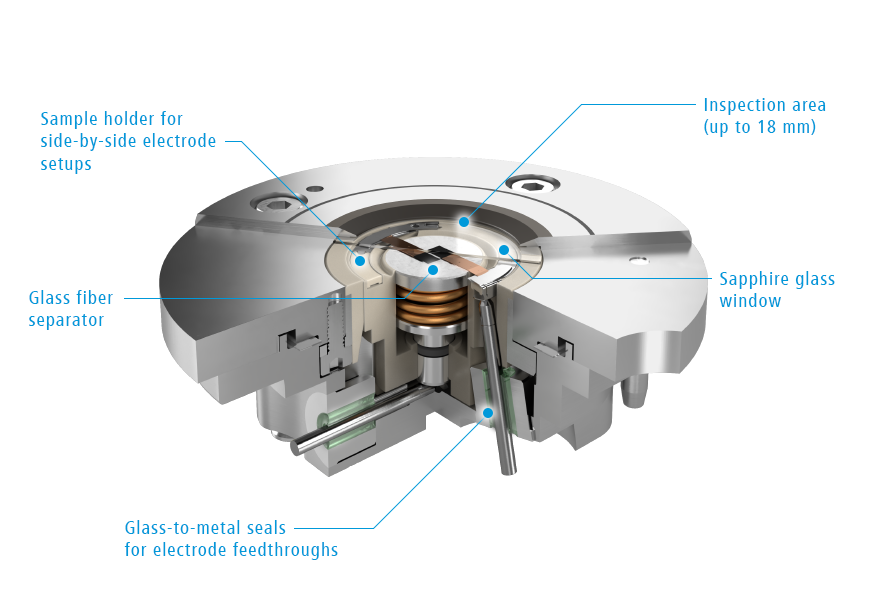

A newly developed sealing concept utilizing laser-welded glass-to-metal electrode feed-throughs and foil seals substantially increases cycle stability compared to the previous generation. We further optimized the cell design for easy assembly. Dedicated sample holders for side-by-side and face-to-face arrangements of electrodes vastly improve the handling.

The PAT-Cell-Opto-10 utilizes the cableless PAT socket for cell connection. This way, it can be directly plugged into a PAT battery tester like the PAT-Tester-x-8 or a PAT docking station to connect it to a third-party battery tester.

PAT-Cell-Opto-10 overview

High cycling stability due to improved sealing concept

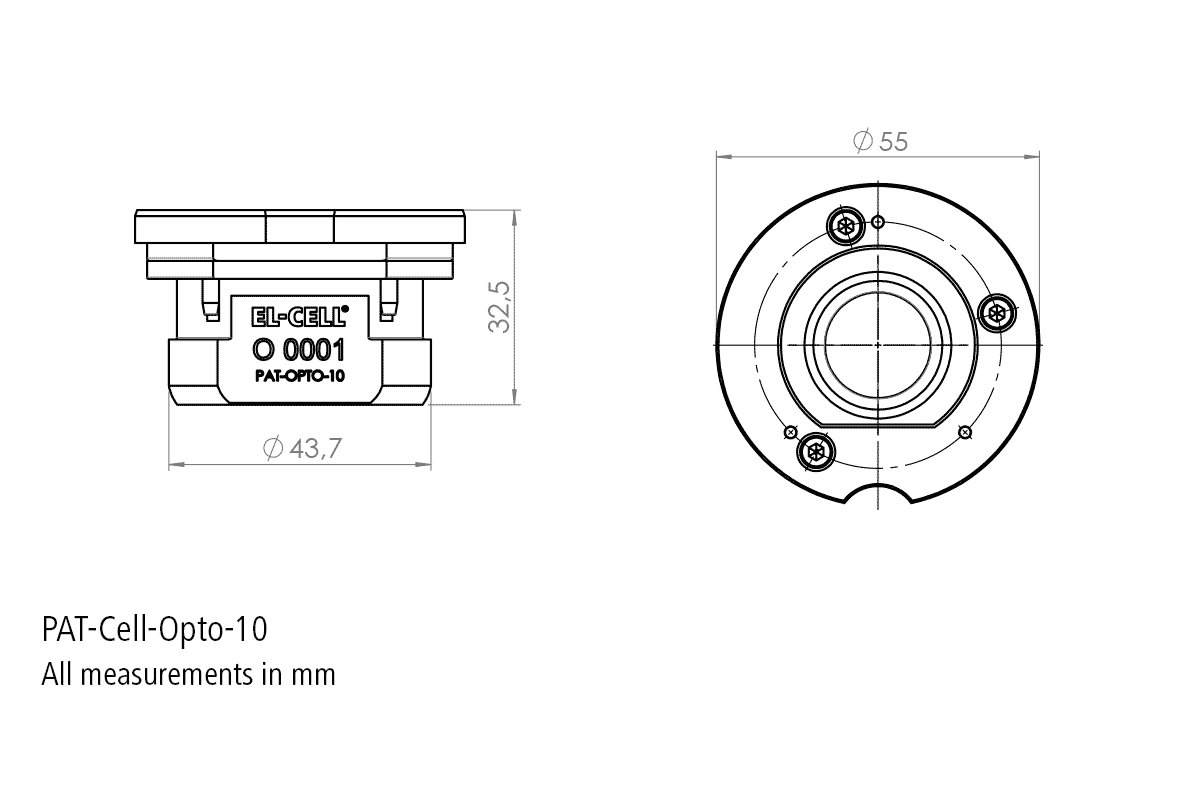

Dedicated sample holders for different electrode arrangements available Fast assembly and dismantling and easy cleaning of cell components Electrodes are easily accessible for post-mortem analysis Cableless cell connection via PAT socket| Height | 32 mm |

| Width | 55 mm |

| Depth | 55 mm |

| Electrode dimensions | up to 10 mm |

| Weight | 0.3 kg |

| Operational temperature range | -20° to +70°C |

| Dead volume | 1.8 cm³ |

| PAT-Cell-Opto-10 User Manual | |

| Release | 1.31 | |

| Date | December 2024 | |

| Type | ||

| Size | 1.8 MB | |

| Download |

Accessories

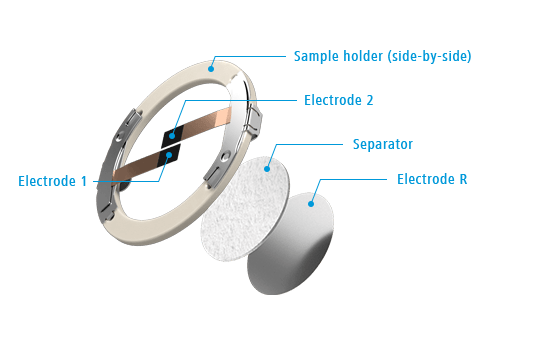

Dedicated sample holders

Improve your workflow and save time with our sample holders for side-by-side and face-to face arrangements of electrodes. Both variants are included with each PAT-Cell-Opto-10 or ECC-Opto-10!

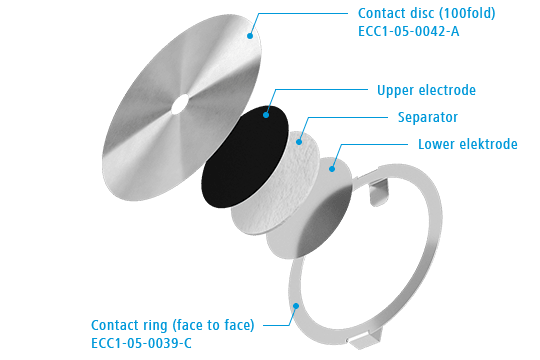

Sample holder (side-by-side)

Sample holder (face-to-face)

Contact discs with 1, 2, and 4 mm opening are available and included with each test cell.

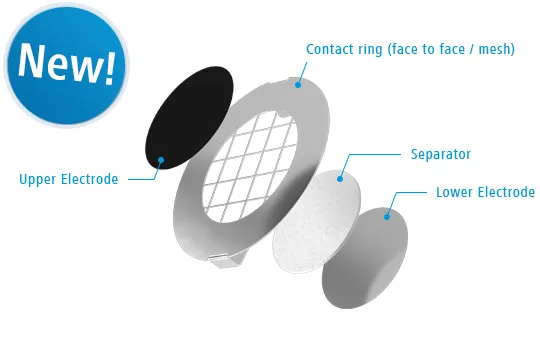

Sample holder (face to face with mesh)

Videos

PAT-Cell-Opto-10: Long term cycling of graphite vs Li in face-to-face mode (09/2021)

In this video, Dr Matthias Hahn demonstrates the outstanding cycling stability and tightness of our new optical battery test cells.

For this purpose, we cycled graphite against lithium for approx. 400 hours (25 cycles) in a PAT-Cell-Opto-10. A PAT-Tester-x-8 was used as potentiostat while the data was evaluated in EL-Software.

As you can see from the curves shown, the die capacity retention of the test cell at the end of the experiment was still around 80% with a Coulomb efficiency of almost 100%.

PAT-Cell-Opto-10: Assembly procedures for side-by-side electrode setup (10/2022)

In this video, Dr. Matthias Hahn shows the required steps for assembling the test cell in the side-by-side electrode setup inside the glove box.

PAT-Cell-Opto-10: Assembly procedures for face-to-face electrode setup (10/2021)

Learn how to assemble the PAT-Cell-Opto-10 optical battery test cell in face-to-face electrode setup.

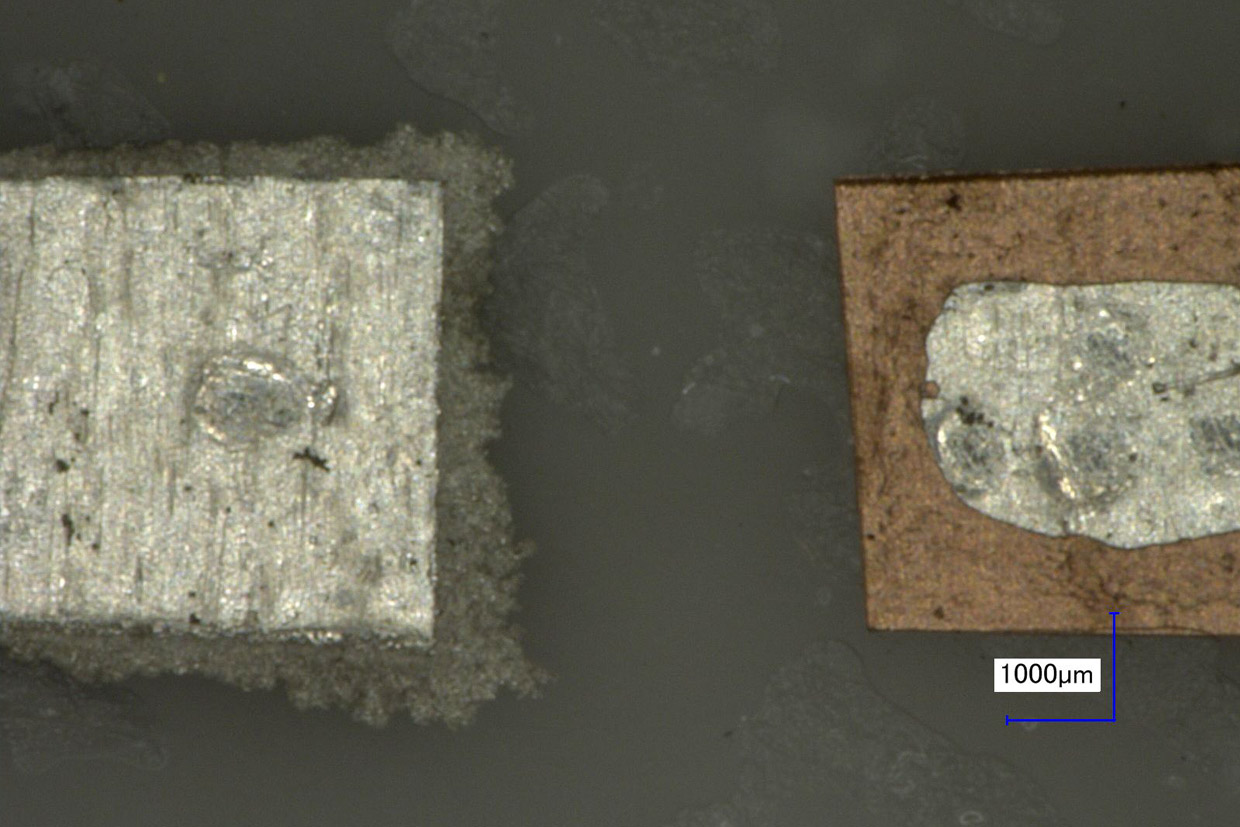

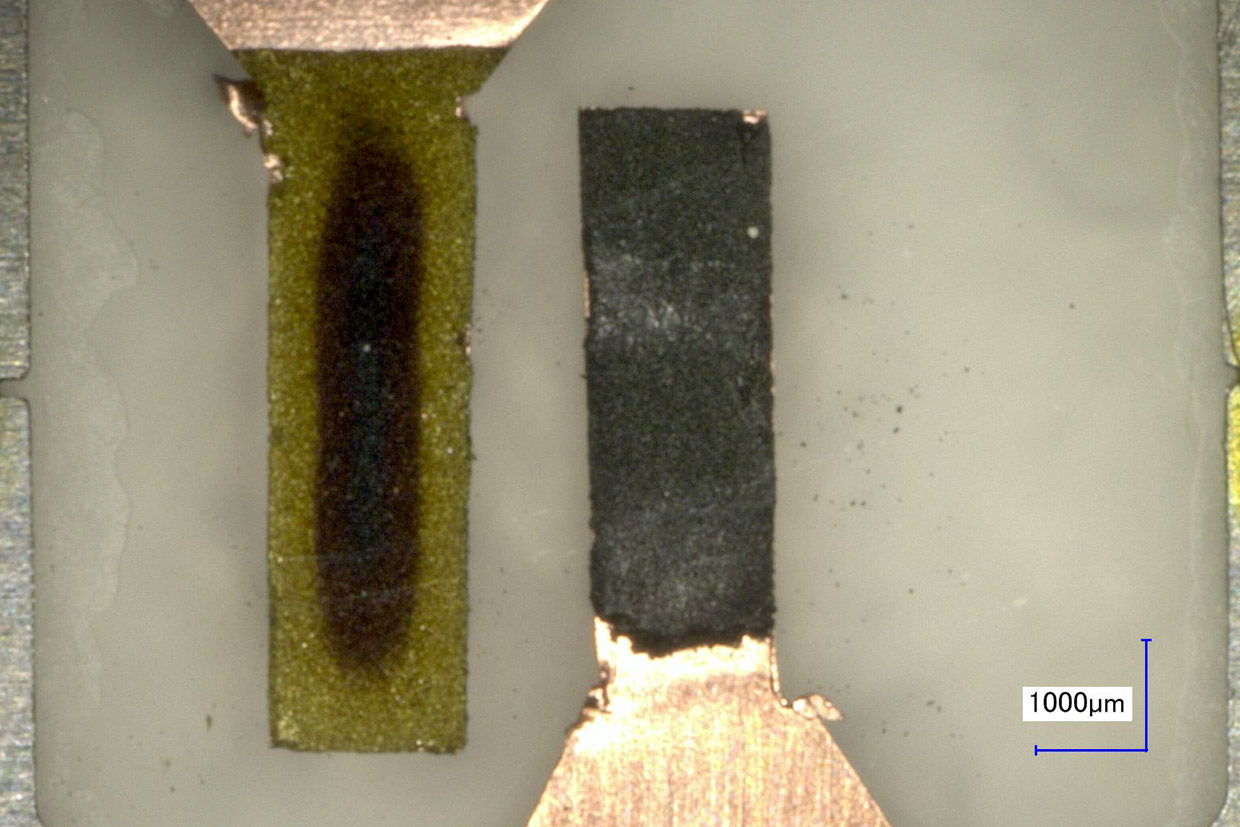

Sample test results

The picture shows two lithium metal electrodes – 20 µm lithium foil laminated on copper foil – beneath the sapphire window of the test cell. The electrodes are embedded into a glass fiber separator soaked with electrolyte. Applying a current of 20 µA for 5 hours makes the lithium to dissolve from the supporting copper foil (right electrode) and to plate as dendrites on the opposite side (left electrode).

The picture shows two graphite electrodes embedded in a glass fiber separator soaked with electrolyte. The graphite electrode on the left is being lithiated from the lithium metal electrode below the separator. From the color change, one can infer the lithiation gradient within the graphite electrode. The right graphite electrode can be used in a follow-up experiment to send lithium ions back and forth between the two graphite strips.

Gallery

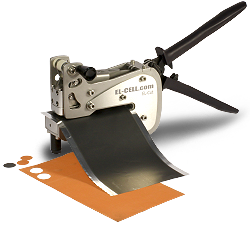

Recommended tools

EL-Cut

High Precision Cutting Tool eliminates torn and chipped electrode edges. The recommended size for use with the PAT-Cell-Opto-10 is 10 mm.

ECC-LiPunch

Punching tool for lithium foil. The recommended size for use with the PAT-Cell-Opto-10 is 10 mm.

Related products

PAT-Tester-x-8

Fully featured potentiostat / galvanostat / impedance analyzer with up to 8 channels for small scale and special purpose testing.

ECC-Opto-Gas

Test cell for optical characterization of gas diffusion electrodes in metal-air batteries.